Hello, this is HDC.

Today, Japanese drainage facilities We introduce a case study of metal 3D printing conducted by Daidore, a specialized company.

Complex piping parts that previously had to rely on casting methods, Fast and flexible without molds It's a very impressive project in terms of what can be produced.

This is particularly helpful for industrial sites that require complex shapes, small-scale production, and customization.

The Limitations of Casting and the Flexibility of Additive Manufacturing

Daidore is a Japanese company that manufactures drainage facilities, manholes, and water treatment equipment.

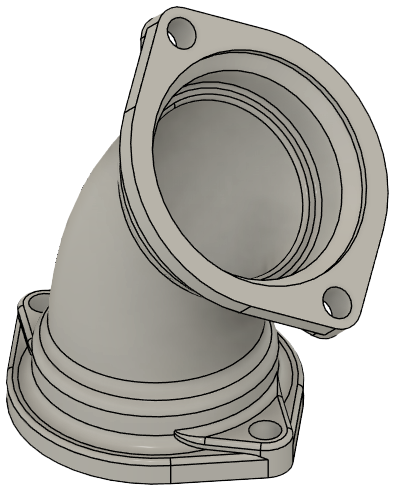

In this project Corrosion-resistant elbow pipe for special piping that does not conform to standard specificationshad to be produced,

The existing casting method was inevitably time-consuming and costly.

Casting is a widely used method for manufacturing pipe fittings,

Once a mold is created, it is difficult to change its shape, and it is inefficient for short-term production or prototype production.

Customization was particularly challenging when it came to mold manufacturing, as there were significant constraints on mold manufacturing time, cost, and shape flexibility.

| Even complex shapes can be produced in a short time without a mold

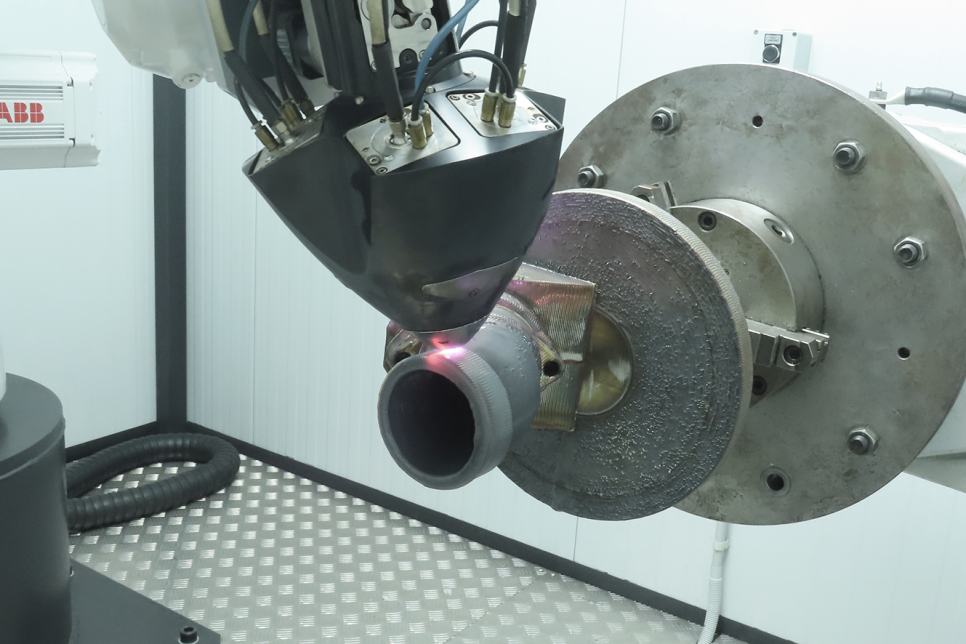

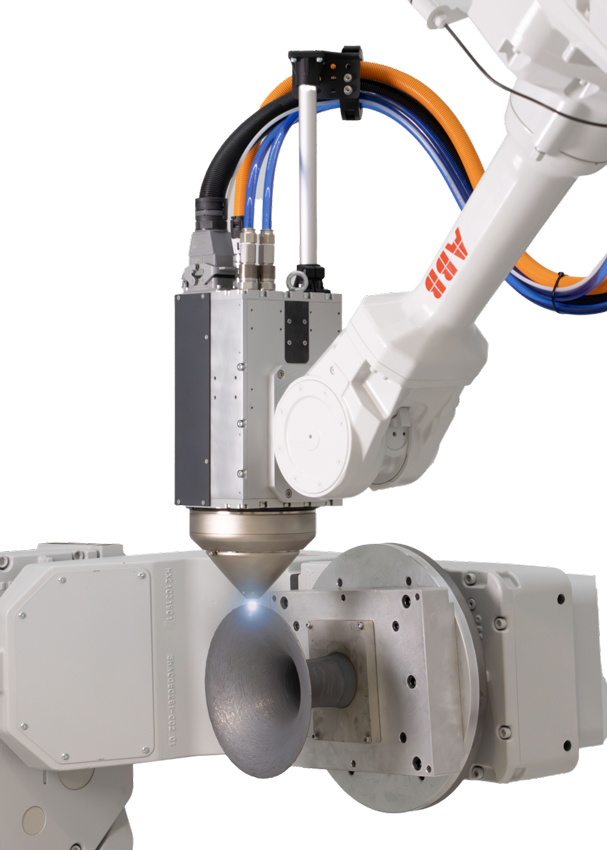

Daidore uses Meltio's robotic arm integrated additive manufacturing system (Meltio Engine for Robotic arms)

The part was printed directly from stainless steel SS316L.

The output size is 165.7 × 107 × 174.7 mm and the weight is 3.3 kg.

With a layer height of 1 mm Output completed within 16 hoursIt's done.

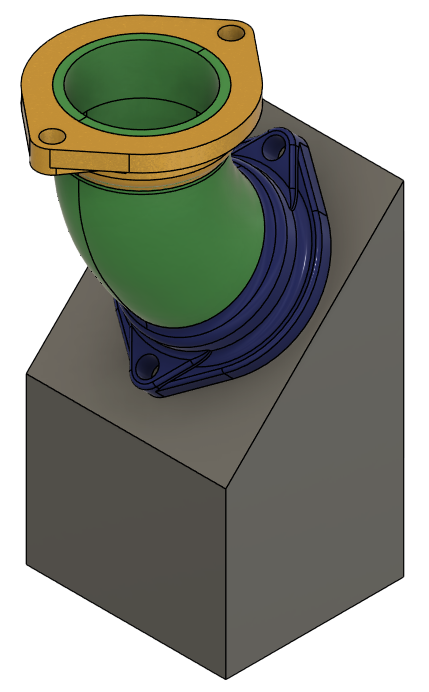

Meltio's Radial stacking strategyclass Custom tooling design Thanks to you,

It was possible to optimize the flange direction and output it without a separate support structure.

Complex shapes that were previously difficult to create can now be easily implemented.

| Efficiency achieved without process design or production line changes

Meltio's Tool-free (no mold required) Thanks to this approach, Daidore can produce without separate mold design or production line reconfiguration.

Robotic automation has enabled unmanned production.

The radial output strategy is also suitable for complex geometries. Stable and reproducible I made it,

We were able to efficiently manage both inert gas usage and energy consumption.

-

-

Implementation of complex shapes without mold design

-

Can be printed without separate processing or support structures

-

Shortened production time (printing completed within 16 hours)

-

Highly reproducible precision output

-

Reduce manufacturing costs and increase production flexibility

-

| Equipment and specifications used

-

-

equipment: Meltio Engine Integration Kit for Robotic Arms

-

Areas of application: Industrial (on-site custom order production)

-

subject matter: Stainless Steel 316L (excellent corrosion resistance)

-

Printing time: about 16 hours

-

This case goes beyond simply replacing the casting.

Flexible design, fast delivery, high-quality outputSatisfying all at once

It can be said that it has presented a new direction in the manufacturing of industrial metal parts.