Hello, this is HDC, a consulting firm specializing in AM solutions.

Design and production innovations leveraging metal additive manufacturing technology are rapidly spreading across the agricultural sector.

In particular, WLMD technology, which can produce complex parts more flexibly and efficiently, is used in fields requiring small-scale production and customized parts production.

We are opening up new possibilities,

Today, Autodesk and Unverferth present a case study demonstrating the potential of Meltio technology.

Autodesk is a global leader in design and engineering software, driving innovation across industries with powerful tools like Autodesk Inventor and Autodesk Fusion 360.

Unverferth Manufacturing, a renowned agricultural equipment manufacturer, is constantly exploring new ways to improve the efficiency and performance of its production processes. Let's explore how these two companies have come together to transform the durability and production of agricultural equipment.

A harsh environment that even the strongest components struggle to withstand.

Injection knives used in agricultural equipment are key wear parts that cut the soil and inject fertilizer or slurry.

However, these parts have been manufactured using conventional casting and machining methods and have encountered several chronic problems.

- High wear and corrosion due to soil abrasion and chemical exposure

- Complex shapes that are difficult to process (narrow gaps or hard-to-reach areas, etc.)

- Risk of deformation due to elongation of parts

- Long production times and high costs due to mold making and casting

- Due to the demand for small-volume service parts, conventional methods are not economically feasible.

Especially since agricultural equipment is often used for decades, not only current models but also older equipment Supplying parts at a reasonable costThis is becoming an increasingly bigger challenge.

A new injection knife to solve an old problem

Conventional injection knives are made of cast and then hardened steel parts, making it difficult to machine slots in hard-to-reach locations due to their structure, and there is also a risk of deformation due to the height of the parts.

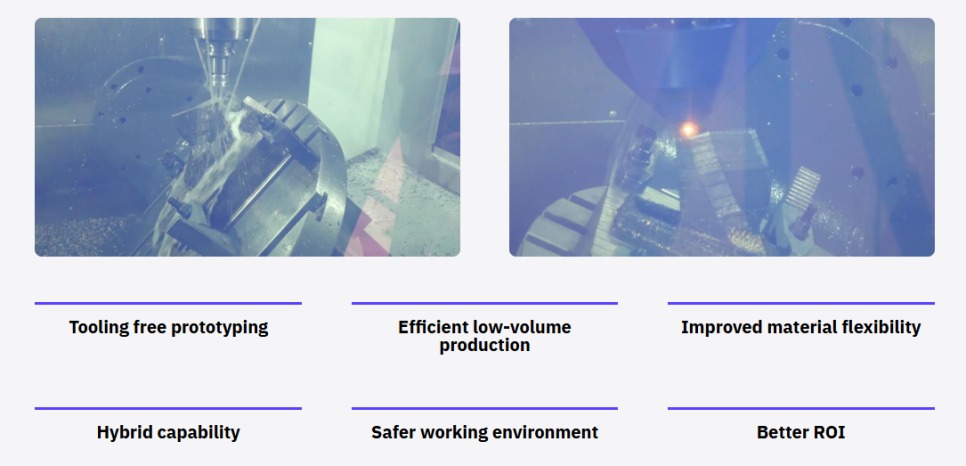

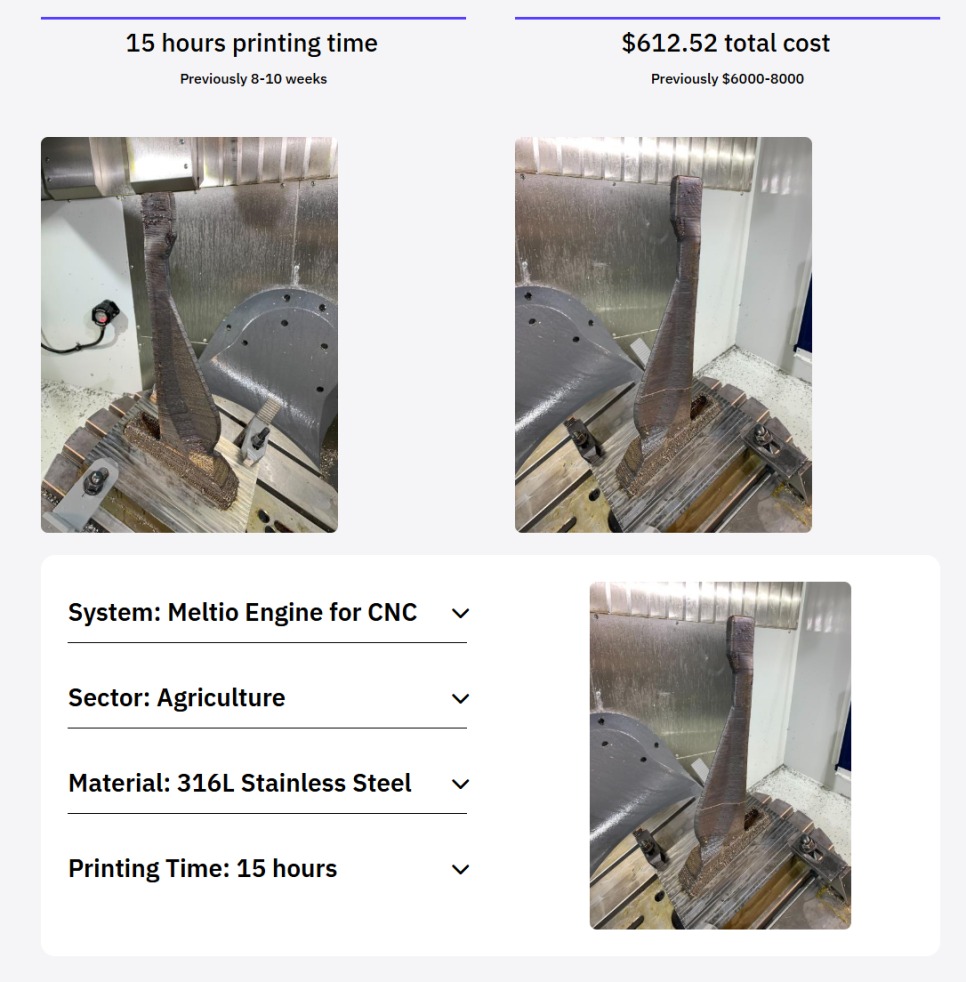

To overcome these limitations, Autodesk Meltio Engine for CNCwas introduced.

This equipment is an integrated kit that adds hybrid manufacturing capabilities to vertical machining centers, combining wire-fed laser metal additive technology with a traditional CNC platform.

Autodesk redesigned the injection knife, eliminating traditional design and production constraints thanks to Meltio's hybrid system.

Thanks to this, we were able to freely manufacture even the difficult-to-access slot parts, and we were able to add material precisely to only the necessary parts to prevent deformation due to the length of the part. Two-step printing methodwas able to apply.

Same quality, lower cost and lead time

Applying Meltio Technology in Agriculture

Easily create prototypes of cast and forged parts without expensive molds.

Meltio technology enables rapid production without the need for separate mold investments, significantly increasing design modification and development speed.

Also advantageous for producing small quantities of service parts

Because most agricultural equipment is used for decades, parts for older machines often need to be produced only a few times a year.

In such cases, Meltio's hybrid method allows for economical production of only the amount needed without the need to manufacture and manage multiple jigs or fixtures.

Especially in today's challenging supply chain environment, it is a highly effective solution for small-batch castings and forged parts.