Hello, this is HDC.

Today, Meltio's WLMD (Wire-Laser Metal Deposition) technology is being used in the field of automobile racing (motorsports).

Let me introduce you to how we are providing innovative solutions.

Motorsports is a field with very demanding requirements that are on a different level from other industries.

Most racing cars are redesigned each season, requiring custom parts for prototypes or small-scale production runs.

However, simply ‘making’ these parts is not enough.

- Ensuring strength and rigidity

- Meets lightweight standards

- Production within short lead times

Because all of these conditions must be met simultaneously, a high level of flexibility and efficiency is required during the manufacturing process.

Complex and Demanding Requirements: A New Answer to Automotive Racing Parts Manufacturing – Meltio WLMD Technology

In fields such as this, where complex and rapid responses are required, traditional methods such as existing processing and welding have clear limitations.

This is especially true because it's difficult to efficiently manufacture complex parts. However, it's premature to assume that technologies like additive manufacturing (LMD, Laser Metal Deposition) are inherently difficult. In fact, these limitations present opportunities for innovative manufacturing methods to shine.

The strengths of hybrid manufacturing (cutting + lamination) that overcome the limitations of traditional methods allow for the efficient production of complex shapes.

Today, Hirudi, Meltio's sales partner, will introduce the potential of Meltio's Wire-Laser Metal Deposition (WLMD) technology in the production of automotive racing parts. Furthermore, we'll explore how Meltio's technology can be applied in a variety of industries requiring complex shapes.

index

- Application Overview: Key Features and Descriptions

- Essential requirements for component manufacturing

- Key conditions for efficient parts manufacturing

- Main objectives

- Component Analysis: From Design to Manufacturing

- Manufacturing Optimization: The Role of Iterative Improvement

- Manufacturing process characterization

- Simulation-based verification (finite element analysis, FEA)

- Machining

- Notable results

- Expandable future possibilities

- conclusion

1. Application Case Overview: Key Features and Description

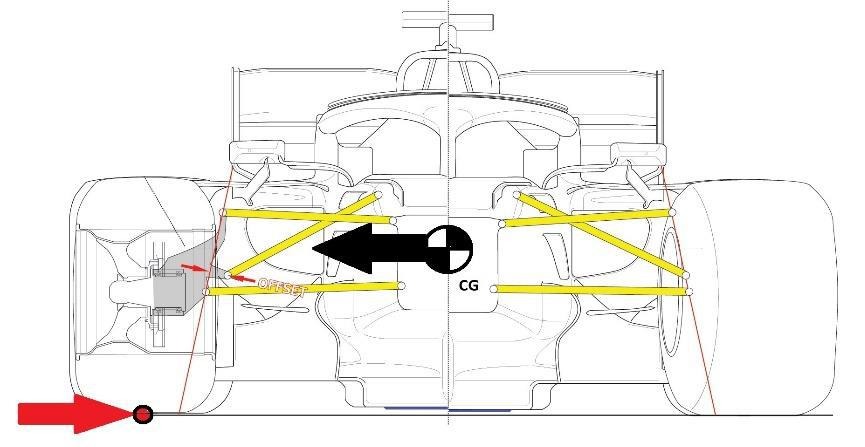

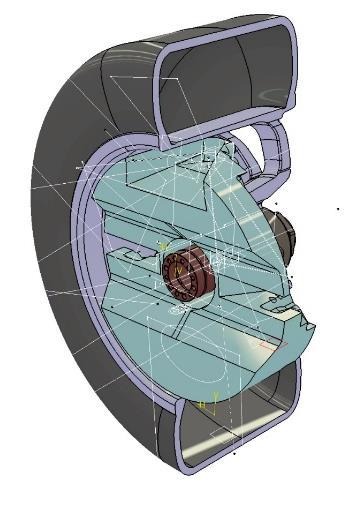

In this project, we will study the suspension system of a mountain climbing racing car prototype.

The Meltio system was applied to the stub axle, which plays a key role.

This component plays a crucial role in transmitting power between the wheels and the vehicle body. The force generated at the contact point between the wheels and the ground is transmitted to the vehicle body via the suspension arms, ensuring optimal handling performance and driving safety.

2. Essential requirements for manufacturing parts

The design of a stub axle begins with geometrical conditions and operating environment.

First, ensure that the part is properly secured to the vehicle and that the machining tool has easy access. Design volume (space)Defining is key.

The three most important goals in this part are: strength, stiffness, lightness no see.

But these are not problems that can be solved simply by calculation.

Finding the optimal balance through multiple iterations of design and verification is essential, and this is where hybrid manufacturing technology plays a major role.

This is because it allows for the simultaneous implementation of complex shapes and material optimization by maintaining the advantages of existing processing methods and adding cutting-edge technologies such as 3D printing.

Ultimately, this approach opens up new possibilities for making automotive components more efficient and sustainable, and meeting even the most challenging design requirements.

3. Key Conditions for Efficient Parts Manufacturing

Stub axle design utilizing hybrid manufacturing methods is a promising approach in automotive engineering.

It was an innovative attempt to explore new possibilities.

The initial design will focus on sheet metal work and machining, maximizing the advantages of existing processes while:

It was a strategy to minimize limitations and costs.

During the design process

- Required geometric and functional conditions across the vehicle system

- Strength, rigidity, and light weight

We simultaneously considered the core objectives of:

These conditions are for the parts

- Design volume (size and shape)

- Fastening points that connect to other parts

- Tool accessibility and ease of assembly

It becomes the standard for determining the back.

Most importantly, satisfying all these mechanical requirements requires repeated validation and optimization.

Ultimately, the key challenge for this project was to ensure functional and structural integrity while meeting both strength and rigidity standards.

4. Core Goals of the Project

The ultimate goal of this project is Hybrid manufacturing (additive + subtractive machining) conceptThe aim was to explore the possibility of applying it to the production of meaningful parts in real industrial settings.

To this end, we have set the following detailed goals:

■ Implementation of a lightweight yet sturdy design

Leverage the strengths of the Meltio system to solve complex geometry problems,

Rigidity and lightweightCompleting the optimal design that satisfies both conflicting requirements

■ Reduce material waste and processing time

Compared to the existing SLM (Selective Laser Melting) process

Improved metal structure quality while maintaining shape complexityWhile doing so

Reduce raw material usage and processing time Cost savings realization

■ Minimizing process constraints

Compared to existing manufacturing methods Shorter lead times and lower costsBy achieving

Creating efficient solutions that can be practically applied in industrial settings

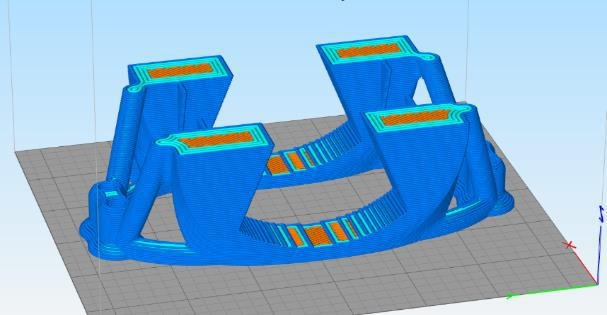

5. Component Analysis: From Design to Manufacturing

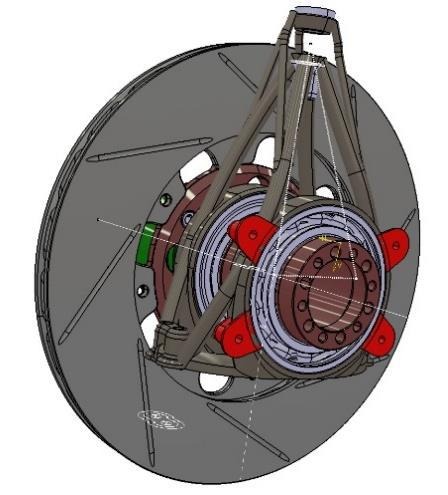

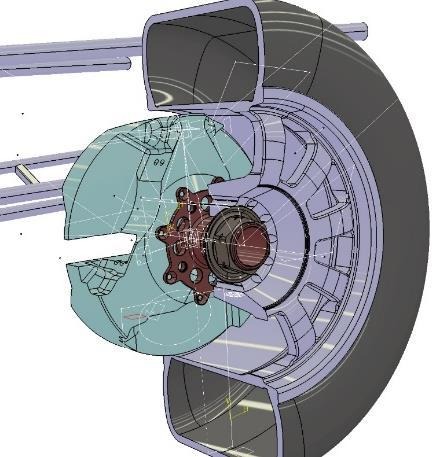

The design of a full stub axle is based on the functional role the part must perform and the manufacturing process.

It has progressed in a way that satisfies all the constraints.

In the initial stages, work was done to optimize the geometry, taking into full account Meltio's additive manufacturing capabilities.

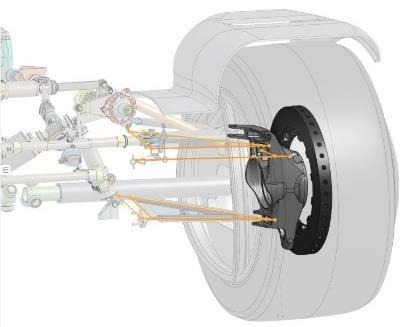

The stub axle is a component that efficiently absorbs and transmits power between the wheel and the body.

A variety of elements make this possible, including bearings, spherical plain bearings, and bolted joints.

The key was to design the structure so that these parts could be organically connected to each other and effectively transmit the load.

At the same time, self-supporting shapes were given priority to increase output efficiency.

This allowed us to minimize separate supports, reducing material waste and production time.

The Meltio system is particularly strong in optimization tasks that focus material placement on high-stress areas.

We were able to maximize efficiency by boldly reducing materials in unnecessary areas while increasing structural strength and durability.

A balanced design that satisfies functionality, durability, and productivity is

This is a prime example of the true value of Meltio's hybrid manufacturing approach.

|

|

|

|

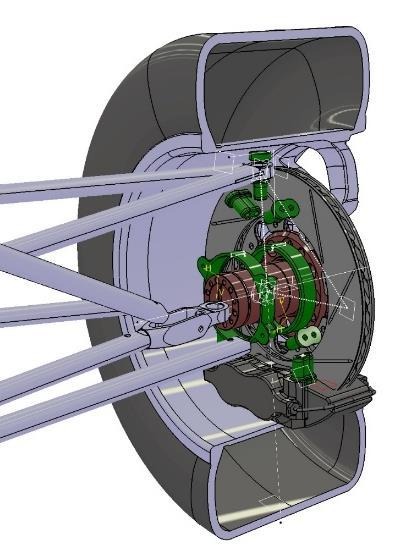

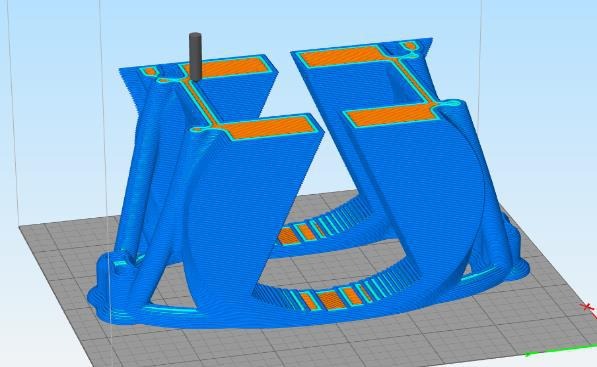

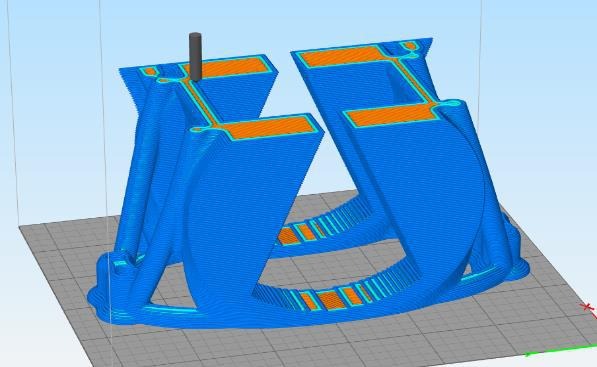

Manufacturing Optimization: The Role of Iterative Improvement

Component design is not completed in one go.

In this project, we achieved optimal results through several iterative improvements.

especially Wall thickness, projection angle, material densityFocusing on key elements such as

Fine-tuning has been done to meet both performance and manufacturability goals.

From the CAD model stage Optimizing the location and shape of support structuresSo,

It is designed to reduce the burden of subsequent processing and minimize material usage.

Complex areas are self-supporting geometry Designed with

We eliminated the need for large-scale external support, thereby increasing both productivity and efficiency.

During the manufacturing process, various parameters are carefully adjusted. Reduce geometric constraints and maximize output qualityThe work continued.

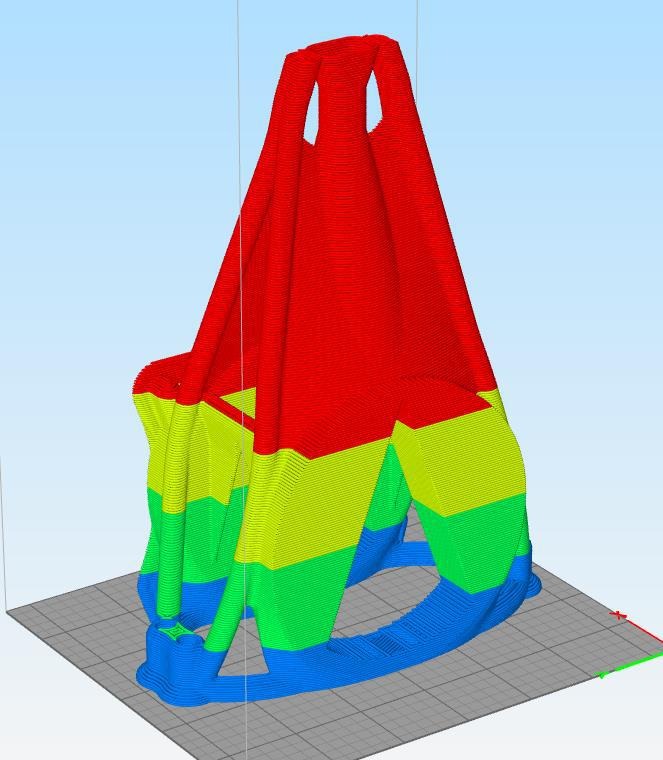

Especially the parts Divided into several zones (fragments) according to production difficulty and shape characteristicsWe used the approach of doing.

■ Key optimization points

- Isolated surface areas in the form of islands: Energy and material flow are precisely controlled to prevent overheating during printing.

- Overhang angle adjustment : The angles have been carefully adjusted to ensure stability and precision even on large protrusions.

- Path Overlapping Optimization: The path overlap has been optimized to ensure proper material fusion and structural strength.

Through this process, each area was precisely adjusted,

The end result is a smooth and robust part.

▶ Manufacturing process characterization

Based on the results obtained through testing, the final part was manufactured using different layering settings for each zone.

Each section is Floor height, exterior wall thickness (perimeter number), energy input, material supply rate Each process is individually optimized by adjusting various process variables.

During this process, the design team actively tested the limits of specific parameters.

for example, Cantilever angle, wall thickness, and minimum manufacturable cross-sectional area We challenged difficult shape conditions through experiments.

These attempts are not simply to obtain data, but to investigate potential issues that may arise during actual manufacturing. Clearly identify constraintsIt was a strategic approach to do so.

Ultimately, this allowed the design team to accurately understand the limitations and possibilities of the Meltio system and establish optimal design criteria for successful manufacturing.

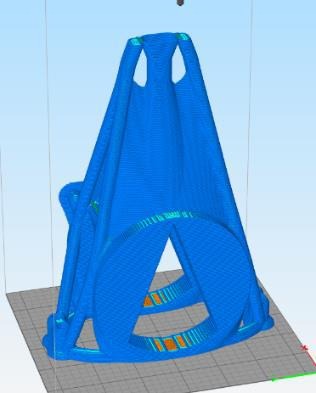

|

|

|

|

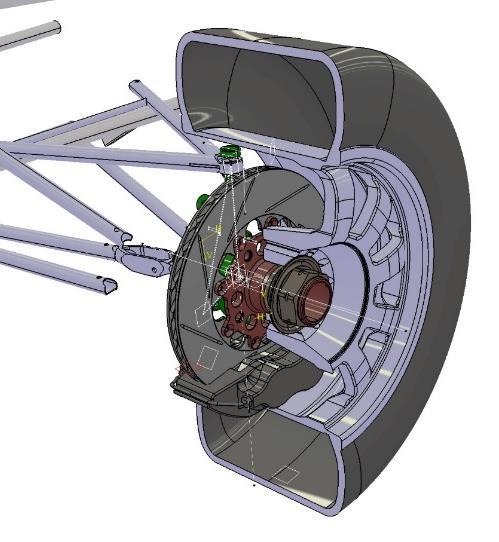

After clearly identifying the process limitations and constraints, the design team quickly made necessary modifications and improvements.

Based on the results Manufacturing actual-size parts (full-scale manufacturing) , and carried out

This process was also successfully completed by actively reflecting the data obtained from the test.

What is particularly noteworthy about this project is that:

▶ Thanks to the hybrid manufacturing method, conventional methods

Implement complex shapes that were previously difficult or impossibleThat it was possible.

This means that the Meltio system goes beyond simple lamination equipment.

This is a significant example of a robust, scalable manufacturing solution that can be deployed across a wide range of industries.

The true appeal of Meltio technology lies in its ability to freely implement complex shapes while still enabling efficient manufacturing.

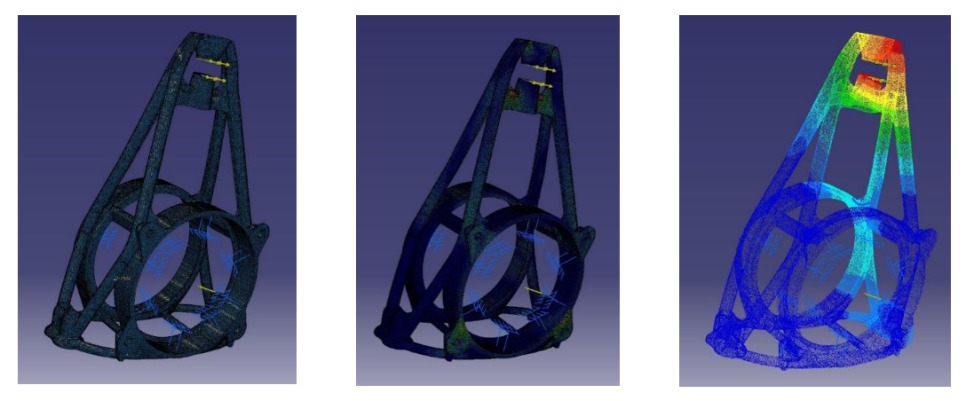

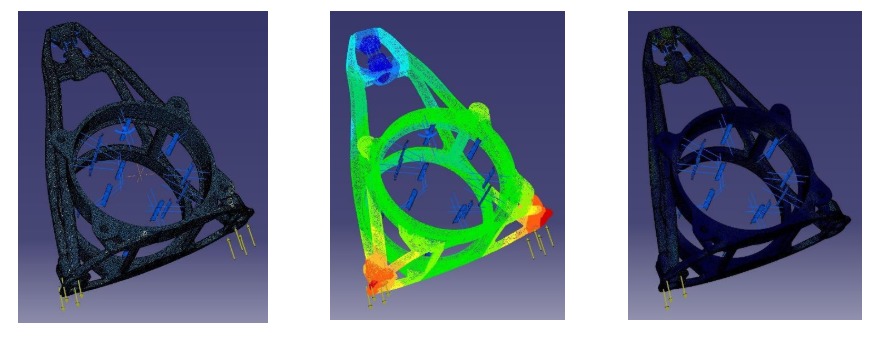

▶ Simulation-based verification (FEA)

When designing high-speed racing parts Finite Element Analysis (FEA) is an essential tool.

This is because the actual driving environment can be virtually implemented and the performance of components under lateral (horizontal) and longitudinal (vertical) loads can be verified in advance.

This allows us to thoroughly check whether the design is sufficiently reliable before going into full-scale production.

In this project, every time a design change was made, performance verification was performed through FEA.

Even if only some sections are adjusted, ultimately Integrated review of all componentsWe have gone through a process to ensure that all parts meet the required performance standards.

The materials used to make the parts are ER70S6 mild steel was selected as .

This material is suitable for racing parts requiring precision work due to its excellent weldability and machinability.

Additionally, to precisely simulate complex shapes, mesh convergence study Also performed.

Through this, we found the optimal element size that could satisfy both efficient simulation and accurate results.

■ Side load & longitudinal braking load simulation

The key to this analysis was simulating two loading conditions.

- Lateral load

- Longitudinal braking load

Especially for lateral loads, 2G acceleration situationWe analyzed it assuming that

Here, the expected ultimate loads in both the horizontal and vertical directions were simulated by applying a safety factor.

The suspension arms were designed to allow for a certain degree of elastic deformation under excessive load.

This ensures that the components are designed to handle real-world racing situations while still being safely protected.

■ Longitudinal braking load simulation

Next is 2.5G braking acceleration situationWe simulated longitudinal load cases assuming .

At this time, both vertical and horizontal forces are applied, and a safety factor is applied to reflect extreme situations that may occur during actual driving.

However, in this interpretation, bearings or joints Auxiliary parts not included.

These parts serve to increase the rigidity of the entire system when actually assembled, but

In the analysis, the stub axle itself was excluded to focus on verifying its performance.

Nevertheless, the results obtained through FEA are,

This proves that the part is designed to withstand high-speed racing environments.

It ensures both safety and performance.

Ultimately, thanks to this meticulous verification process, we were able to create reliable parts from the design stage.

Later, we were able to guarantee its performance in real driving environments.

6. Machining

The fabrication process was considered along with the design process from beginning to end.

Because it is clear what parts can be processed and what parts cannot,

Even at the design stage Processability (limitations imposed by the processing process) We have always kept this in mind when developing.

Only after full-scale development is completed Detailed machining drawingsOnce this is produced, the actual processing work begins.

However, the scope of application of processing is limited.

- The joint where commercial parts are assembled

- Parts where support was added during the design process

Only these two areas were set as processing targets.

This reduces unnecessary processing time,

We were able to maximize the benefits of hybrid manufacturing.

7. Impressive results

What we have confirmed through this project Results of the Meltio hybrid processhas literally become a fantastic example of the possibilities of this technology.

We achieved three goals simultaneously: performance, quality, and cost reduction, while efficiently manufacturing complex shapes.

▶ Weight loss

- Compared to existing processing methods, we were able to reduce the weight by a whopping 62.5%.

- This provides significant advantages in the racing field where weight reduction is crucial.

▶ Cost reduction

- By reducing material usage and processing time, we were able to reduce manufacturing costs by 35.7%.

- It's a way to achieve both efficiency and economy.

▶ Shortened delivery time

- The production period was also shortened by 33%.

- Thanks to this, we have secured a strength that allows us to stay one step ahead even in a highly competitive market environment.

▶ Creating complex shapes

- Complex shapes that were difficult or impossible to produce using conventional methods can now be easily implemented thanks to the hybrid approach.

These achievements also clearly demonstrate the flexibility and scalability of the Meltio system.

It has once again proven that it has great applicability in various industrial fields.

8. Future possibilities for greater impact

Meltio's hybrid manufacturing technology doesn't stop there.

There is potential for expanding our influence in more fields in the future.

- Expanding titanium applications

– Applying titanium to the Meltio process can further reduce weight and processing costs.

– Especially in fields requiring high-performance components, great results can be expected.

- Robot-linked manufacturing

Combining the Meltio Engine with a robot dramatically increases the degree of shape freedom, maximizing material optimization and design flexibility.

In various fields including the automobile industry Automated production of large partsIt also becomes possible.

9. Conclusion

The goal of this project was to demonstrate how the Meltio system can meet the demands of complex part manufacturing.

And that goal was amply achieved.

Thanks to the hybrid process that combines lamination and cutting,

- lighter,

- Faster,

- More economical

We were able to manufacture high-performance parts.

The result was the ease of implementing complex shapes, increasing productivity, and taking full advantage of Meltio technology.

In particular, it has demonstrated that it can overcome the limitations of the 3-axis LMD system and be competitive enough in the production of lightweight structures.

Now Meltio is ready to make a splash in new markets.