The parts that go into high-performance racing cars aren't just lumps of metal.

It must withstand extreme heat, be produced in rapid cycles, and even take precise post-processing into account.

The case we'll be introducing today is a racing car parts manufacturing project conducted by ERM Fab&Test.

ERM said that in carrying out this project, it had to solve three key challenges: “high-temperature resistance,” “fast delivery,” and “low cost.”

So how did you approach it?

▶ Case study of manufacturing racing car parts that can withstand high temperatures

Case studies developed by ERM

ERM Fab&Test is a specialized company providing innovative solutions in the field of metal additive manufacturing.

We support the introduction of 3D printing technology and metal-plastic integration technology to manufacturers, educational institutions, and defense-related companies.

We assist with overall technology integration from prototype production to mass production.

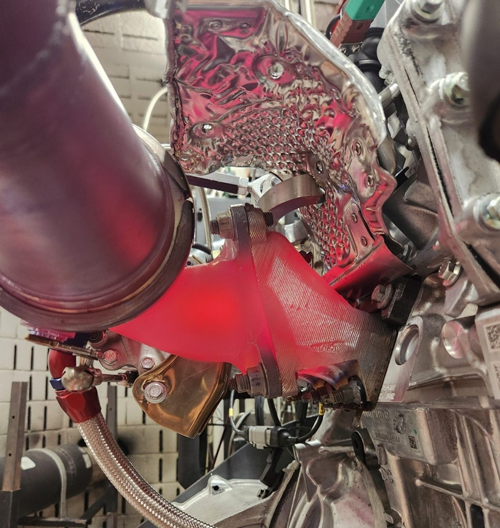

This project started with a client in the automotive industry.

ERM is Manufacturing racing car parts that can withstand temperatures exceeding 800 degrees Celsius in a short period of time.I was asked to do this.

The requirements were clear, Fast delivery, limited budget, high heat resistanceThis was the key.

▶ Demanding industry, demanding parts

Racing industry customers Metal parts that can withstand temperatures exceeding 800 degreesThis was needed.

However, the existing traditional manufacturing method was too time-consuming and expensive to be a realistic alternative.

In addition, if the shape of the actual part to be used (near-net shape) is CNC machined as is, Alignment issues and repetitive setupThis results in decreased productivity

There were frequent issues with delayed delivery.

▶ Achieving outstanding thermal performance even within limited time and budget

The parts produced in this project are It had to be delivered within a short period of time and had to have excellent high-temperature resistance properties.

Maintain precise dimensional tolerances even during post-processingWe had to do it. At the same time, we had to minimize the overall production cost.

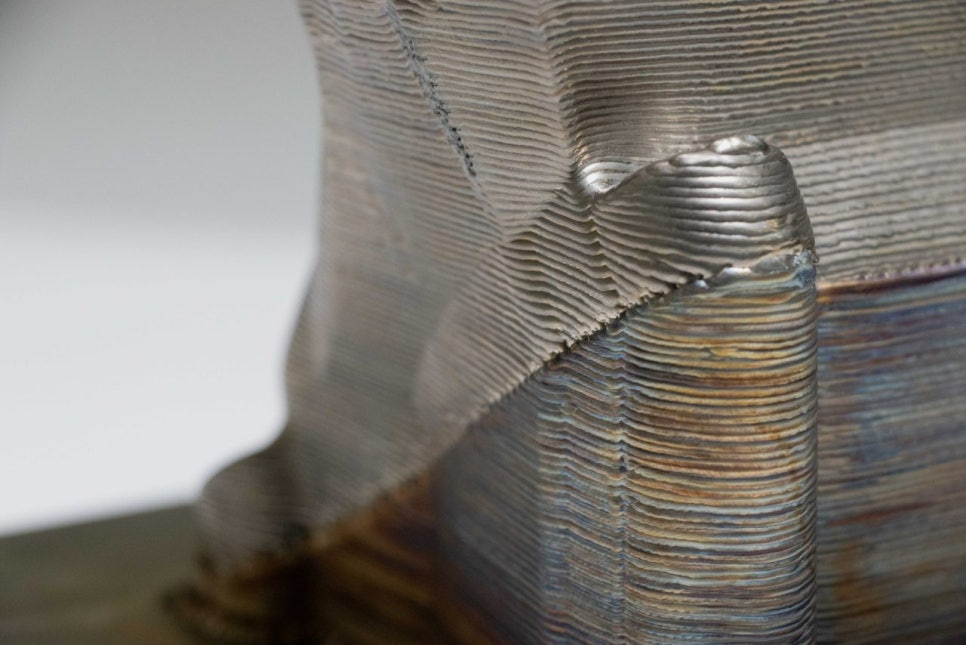

The ERM team is committed to meeting these complex demands. Design custom fixtures after printing the parts to facilitate precision machining.I did,

We applied optimal process design to increase processing efficiency.

| Parts + Support Output

This process outputs nearly finished shapes, ready for reworking within hours. |

Precise Support Output

Support allows the machining center to hold the part precisely at the desired angle. |

Parts machining

By combining output and machining in a hybrid manner, the number of tools can be reduced, reprocessing can be simplified, and overall production time can be significantly shortened. |

This part is Inconel 718 alloyBy using Meltio M600 equipment Direct printing with 316L support structure on a 304L stainless steel baseIt's done.

– Size: 126 × 112 × 134 mm

– Design optimization: no supports, no internal post-processing required

After that, through the Tormach 1100MX equipment Post-processing is performed to ensure accurate machining angles and tool accessibility.The production was done with consideration given to up to .

▶ Achieving both performance and cost with a dual-material strategy.

Another key point of this project is Dual-Material StrategyIt was.

Thanks to Meltio's flexible dual wire system, Cost-effectiveness and performance optimizationWe were able to achieve both at the same time.

Key achievements achieved through this strategy include:

- Production speeds up to three times faster than conventional manufacturing methods

- Optimized machining process flow

- Cost savings of up to 70%

- Ensure high repeatability and production scalability

▶ Fast and accurate processing, simple setup, and uninterrupted process flow

In this way, Meltio's dual-wire system produces high-performance metal parts faster and more reliably.

And it gave us a powerful solution that could make it cheaper.

- Equipment used: Meltio M600

Equipped with a 3-axis probing system and built-in workholding capabilities, the Meltio M600 is a metal 3D printer optimized for manufacturing processes.

- Applicable Industry: Automotive

Designed for on-site custom production and ready-to-print when needed.

- Materials used: Stainless Steel 316L + Inconel 718

Wire-fed methods are a safer and more economical alternative to powder-based methods.

- Output time: 18 hours and 41 minutes total

This project is about more than just successfully creating a single component.

This is because it provides a practical industrial example of how hybrid manufacturing can revolutionize traditional processing-based production methods.

For high-difficulty parts requiring complex shapes, fast delivery, and precision, Meltio's solutions can be an excellent alternative.

Are you curious about the possibilities of additive manufacturing? We'll continue to introduce you to various case studies!