Hello, this is HDC.

Today, we will introduce a method that can effectively control ‘cavitation’, which has been consistently pointed out as a problem in industrial fields.

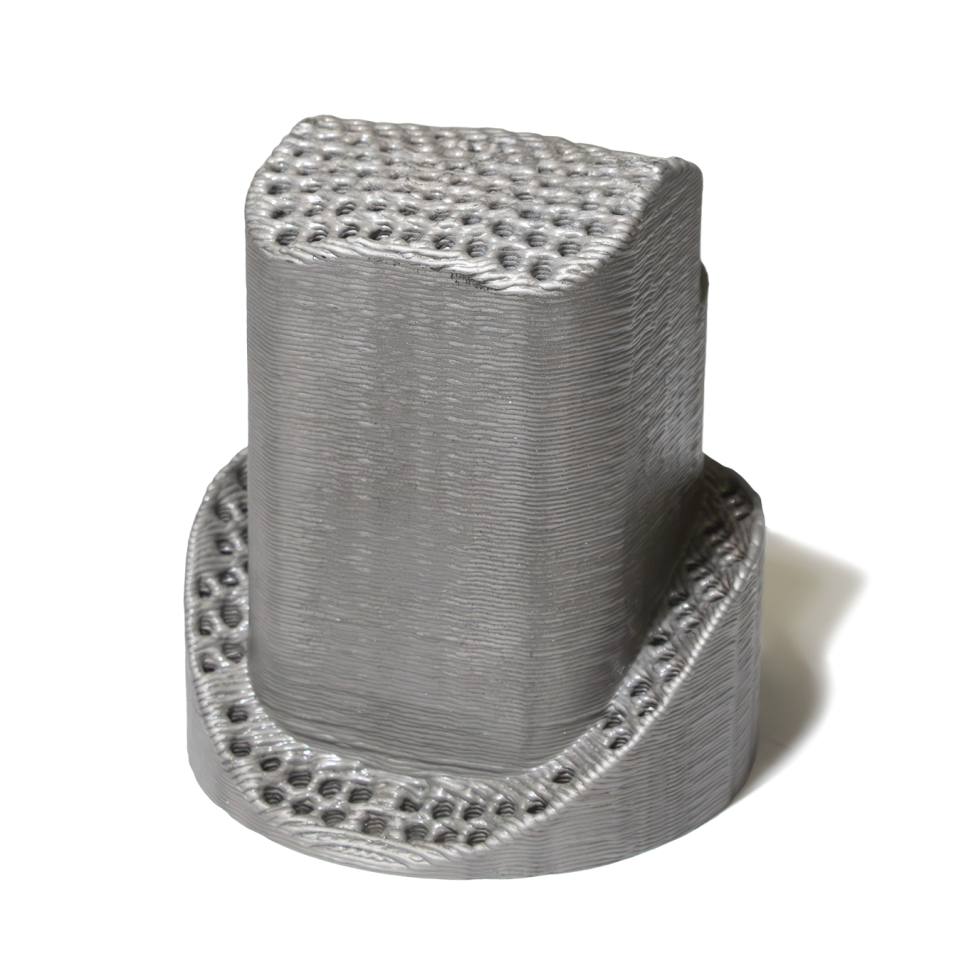

We would like to introduce a case study of an anti-cavitation valve based on metal additive manufacturing.

This part, which previously had to go through complex processes such as casting, machining, and welding,

Here's a real-world example of how Meltio's metal 3D printing technology can be used to produce products much faster and more efficiently.

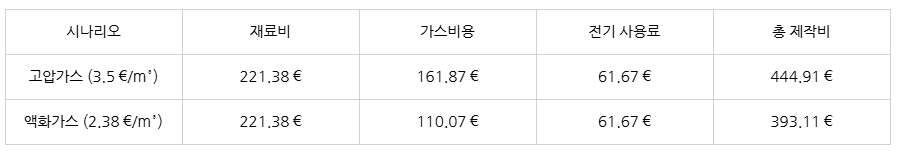

A key point is that the overall cost and time from design to production have been significantly reduced, especially thanks to the internal structure being optimized for additive manufacturing.

|Can additive manufacturing improve the performance of anti-cavitation valves?

When water or fluid flows rapidly in a pipe or pump system,

Cavitation is a phenomenon in which a liquid changes into a gas due to a sudden drop in pressure.

When the bubbles that are created at this time burst again, they enter the valve or pump. By repeatedly causing micro-shocks and corrosion,

It may also cause equipment performance degradation or failure.

Therefore, the ‘anti-cavitation valve’ to reduce this phenomenon plays an important role in protecting equipment even in high-pressure, high-speed fluid environments.

However, these valves were previously manufactured only through complex casting and precision machining, which took a long time and was expensive.

This time, we produced an anti-cavitation valve using Meltio's metal 3D printing technology.

-

-

Simplify the complex manufacturing process

-

While drastically reducing time and cost

-

We have succeeded in precisely implementing high-performance components.

-

Reduced process, reduced cost, faster deliveryIn this respect, the Meltio method shows great potential in industrial settings.

Effective Cavitation Prevention Even in High-Difficulty Fluid Environments

The anti-cavitation valve is a key component that prevents ‘cavitation’ that occurs within a fluid system.

This valve is usually Highly corrosive fluids, high flow rates, and environments with high pressure fluctuationsis used in,

For example, they are mainly installed in industrial sites such as water treatment facilities, chemical plants, and power plants.

Optimized for additive manufacturing from the design stage

Previously, several processes were required to produce these parts, including casting, machining, welding, and post-processing.

The internal Euro design was also complex, requiring precise molding and assembly.

But with Meltio's wire-laser metal 3D printing technology, the overall structure has completely changed.

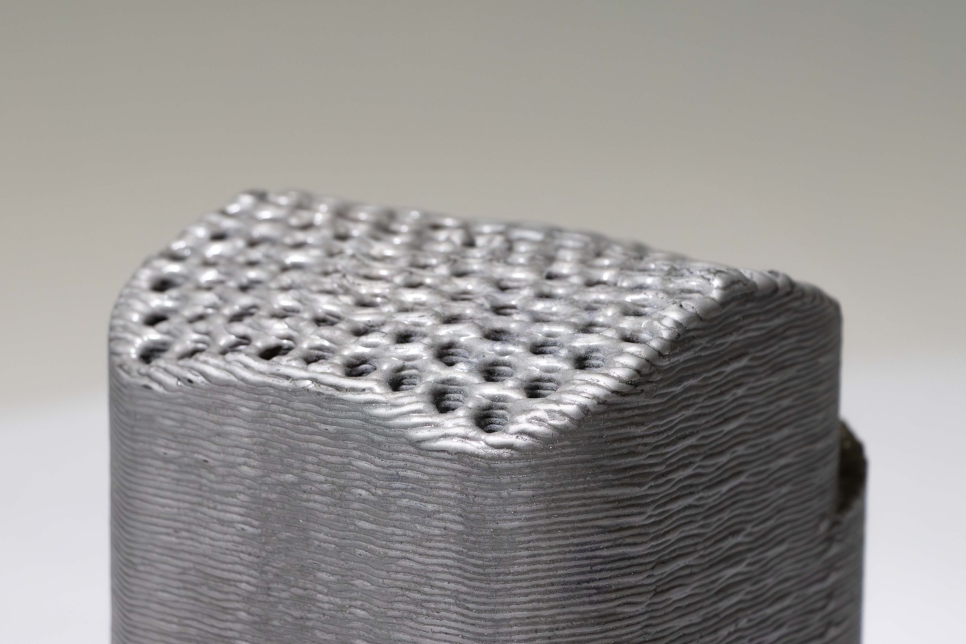

The interior is designed with a honeycomb structure.

To induce a smoother fluid flow, Without any support structures or additional processing Production has become possible.

in result,

Designs are more efficient, processes are simpler, and delivery times are faster.

| Improving Productivity and Cost-Effectiveness with Robot-Based Metal 3D Printing

In this case, not only was an internal structure that was difficult to implement using existing processing methods easily implemented using additive manufacturing, but

It is very significant in that it can be completed without the need for welding, assembly, or separate post-processing.

-

-

Optimized internal design to prevent cavitation

-

High corrosion resistance and high durability material (SS316LSi used)

-

Can be manufactured without internal support or welding processes

-

Realizing increased production speed and cost reduction

-

|

|

| Industrial solutions implemented with Meltio M600

This cavity prevention valve Meltio M600 It was made using equipment.

The M600 is High-power system using blue laser, it has a wide output space and a stable gas control environment.

Maintaining consistent quality of metal materialsYou can do it.

-

-

Areas of application: Industrial (optimized for field-oriented, on-demand manufacturing)

-

Materials used: Stainless steel 316LSi

-

→ than powder material Safer and more economical wire-type material use

-

Printing time: Total 51 hours

-

Output size/weight: 150 x 150 x 180 mm / 12.6 kg

-

Industrial components requiring complex internal euro structures and strong durability Output in one go without welding or separate processingIn terms of being able to do it,

This case once again demonstrates the efficiency and potential of Meltio's additive manufacturing technology.