Hello, this is HDC.

What we are introducing in Korea Meltio's Metal 3D Printing Solutionsthis

In the first half of 2025, we are seeing notable performance across various industries worldwide.

Automotive, defense, aerospace, mining, oil and gas, etc. Harsh conditions and high quality standardsIn this demanding field, Meltio's technology has already passed the 'field test'.

| DED technology attracting attention worldwide

Meltio's Wire-Laser Metal AM Technology is used in automotive, defense, mining, aerospace, oil and gas, etc.

He is active in various fields.

This technology allows you to create the desired metal parts. Produce immediately when neededOr Repair damaged partsYou can do it.

The results are always consistent and highly reproducible, Reduce material waste and cut production time and costsand improves overall production efficiency.

Linares, Spain, July 16, 2025 – Developed by Meltio Directed Energy Deposition (DED) Method metal 3D printing technology

It is receiving increasing attention from various industries around the world.

This technology is different from traditional manufacturing methods. Reduce production time and cost, Repair damaged partsOr Re-manufacture discontinued partsTo do

It delivers outstanding performance.

|Applications in the demanding automotive industry

The automotive industry is a parts High temperature and strong loadIt is a field with high manufacturing difficulty as it must withstand .

Meltio's DED technology is currently being used in the manufacturing of automotive parts, and a representative success story is DMZ's high-performance exhaust manifoldno see.

This part retains its initial condition even after driving for over 10,000 km, and its shape was designed to optimize the complex exhaust flow.

Also, the assembly time is Just 1 hour out of 8 hoursdrastically shortened to global automakers Stellantis Groupof

It met the demanding requirements.

Another motorsports part developed by ERM is turbo intake manifoldIt was produced using two materials together with the Meltio M600 equipment.

This part is High temperature above 800℃can withstand, and compared to traditional manufacturing methods, 70% reduction in production costs and timeIt worked,

In the automotive industry, many companies are also adopting Meltio technology.

for example, Ivecoreduces production lead times by utilizing Meltio Robot Cell solutions at its Bourbon-Lancy, France, plant.

Increased flexibility in component design and manufacturing.

also HirudiIt reduces weight through a lightweight stub axle manufactured with Meltio technology. Reduce by 62%,

Delivery time and cost 33% reductionWe have achieved results.

|Recycling of defense components and supply chain response

Component discontinuation and supply chain disruptions are among the biggest threats to defense operations.

Meltio can print and repair on-site immediately. autonomous systemsWe are solving these problems by providing:

For example, something that was previously impossible to produce 300mm diffuserWe were able to manufacture it using Meltio AM technology and even improved its performance.

Another example is the US Navy's USS Arleigh Burke destroyerUsed in Educer Navy PartsThere is this.

These parts were considered impossible to remanufacture due to their high wear, difficulty in inspection and manufacturing, and long lead times.

Through redesign and material changes Within 58 hours I was able to reproduce it.

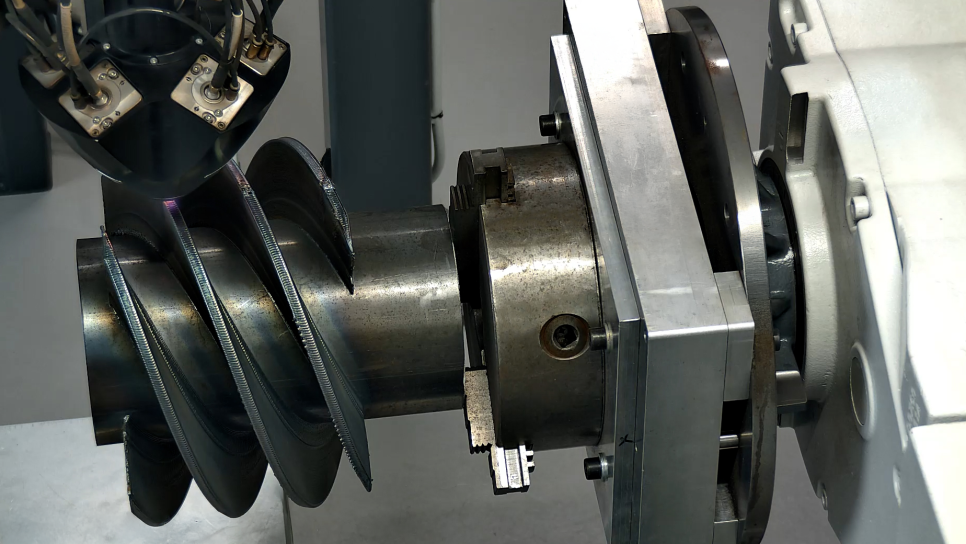

Even complex and durable parts such as impellers have been successfully manufactured using Meltio technology.

Originally a bronze casting part used in a corrosive environment, it was redesigned to increase output and enhance wear resistance.

Material 316L stainless steelChanged to improve performance.

These cases are from all over the world, including the United States, Spain, France, and Korea. Defense sectorIt shows that it relies on Meltio technology.

Ensuring Reliability in the Mining, Oil, Gas, and Energy Industries

Meltio's wire-laser metal 3D printing technology From mine sites to offshore platforms

Delivering outstanding reliability, flexibility, and cost-effectiveness even in the harshest industrial environments.

This technology allows for the production of custom parts without supply chain delays, minimizing equipment downtime,

It can significantly reduce the cost of manufacturing parts.

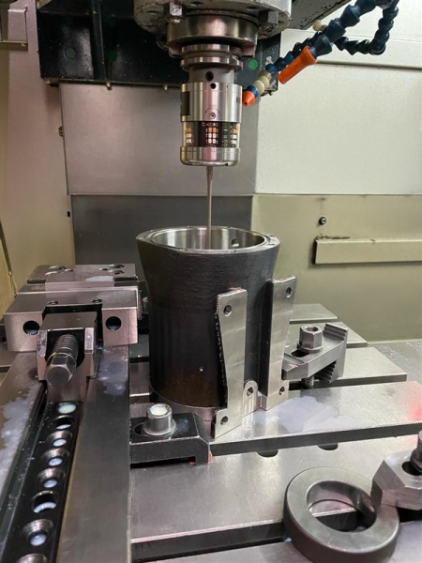

Czech research and development company Roez s.r.o. has developed Meltio technology Single output turbine case The production was successful.

Previously, it was a complex and expensive process, but with Meltio, Produced in just one printBy doing

It saves costs and time, and allows production without additional infrastructure.

Japan – Daidor Corporation

Japanese manufacturing companies Daidoris focused on agile product development and efficient production of industrial components.

Faced with the challenge of streamlining production processes and shortening development cycles, Daidor is developing a solution that can increase both productivity and quality.

We started looking into advanced manufacturing technologies.

After comparing and reviewing various additive manufacturing technologies, Daidor Meltio Robot CellI chose .

The reason is Economy, flexibility, and scalabilityThis is thanks to a unique combination of technologies that simultaneously provide:

Spain – DPR Automatismos

Spanish industrial systems integrator DPR Automatismos We are also manufacturing metal parts using Meltio.

Meltio's laser metal deposition technology Excellent compatibility with robotic systemsand freedom of choice of materials,

And it offers high cost-effectiveness thanks to its ability to implement precise complex shapes.

In addition to France Gary Mécanique, in Mexico ALAR(Aerospace field) and Tecnológico de Monterrey etc.

Companies around the world are adopting Meltio technology and proving its potential.

Meltio M600, recognized by the global industry

The Meltio M600 metal 3D printer 2024 3D Printing Awardsat

It was selected as the ‘Enterprise 3D Printer of the Year – Metals’.

This equipment Copper, aluminum, stainless steel, titanium, Inconel, nickel Ability to handle various metal materials, etc.

It has been highly evaluated for its innovative design and stable quality.

The M600 has revolutionized production lines in various industries including automotive, aerospace, mining, and petroleum.

To both the global industry and the judging panel Reliability and design perfection in manufacturing metal parts using various materialshas been proven.