Hello, this is HDC.

Together with our global partners, HDC provides metal additive manufacturing solutions optimized for domestic manufacturing sites.

What I will introduce this time is Meltio's Heterogeneous material strategy based on ER70S-6no see.

Although mild steel is widely used alone, it is used in combination with tool steels. 74% tool steel savings, 36% cost savings, and 23% shorter output timeIt is a key material that can secure both performance and efficiency.

This strategy offers a practical alternative for everyone, from companies looking to adopt metal additive manufacturing for the first time to industrial sites requiring high-performance parts, so please read through it to the end.

Mild steel (low-carbon steel) is one of the most widely used metals worldwide due to its price competitiveness, workability, and versatility.

Meltio is actively utilizing mild steels such as ER70S-6, which not only provide excellent weldability and ductility, but also

It is also an ideal entry point for companies new to metal additive manufacturing.

While steel is valuable on its own, it actually plays a bigger role in hybrid and heterogeneous applications.

Because it can reduce costs and time while maintaining performance.

|Material Overview

Mild steel belongs to the low-carbon steel category and is one of the most widely used steel types worldwide.

It has a lower carbon content, making it more ductile than high-carbon steel, and is much easier to process and weld, but

It also has the characteristic that hardening or strengthening through heat treatment is almost impossible.

In addition, the steel mainly has a ferrite microstructure. Strong magnetic propertiesThis is interesting,

In fact, in the Meltio application department, we sometimes use a magnet to check when we are not sure what type of steel it is.

This is because the printed parts often look similar to each other.

Mild steel is widely used as ER series welding wire and shows similar properties to other structural steels.

especially Highly attractive for additive manufacturing in terms of cost-effectiveness and material compatibilityThat's it.

Meltio has also tested other steel grades, including ER80, ER100, and ER110, with satisfactory results.

|ER70S-6

The basic grade of steel used in Meltio is ER70S-6no see.

This material shows stable output quality and is readily available in the market.

Compared to stainless steel (316L), the stacking speed is slower, which may result in longer print times when producing large parts.

Even so, there are still significant advantages in that it allows us to keep material costs low.

ER70S-6 is used in various industries such as construction, automobile, and general manufacturing.

In particular, the part that is frequently requested in the market is Heterogeneous material design for cost-effectivenessno see.

Because the steel is easily separated from the build plate, it is also often used for rafting purposes.

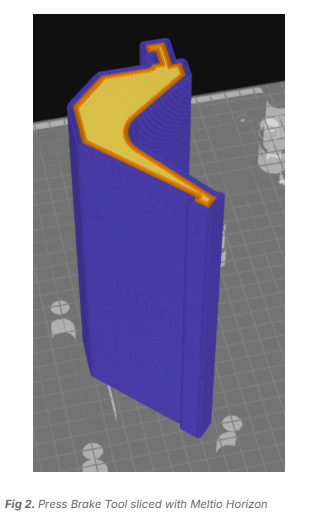

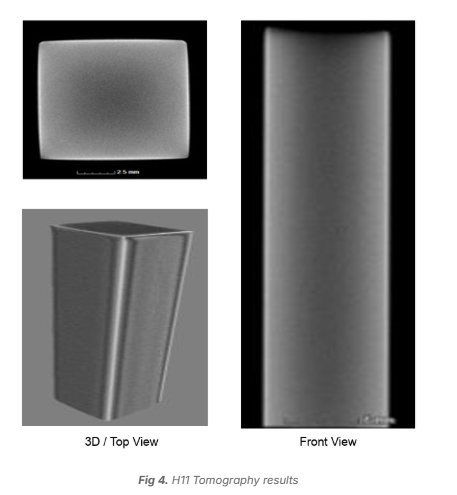

The picture below is an example of a press brake tool.

This tool is widely used in sheet metal forming processes and is applied in various industries.

In this case, the inner core is made of ER70S-6 and the outer core is made of 3mm thick H11 tool steel.

The reason for this structure is clear.

The exterior of a press brake tool is constantly exposed to high wear, pressure, and thermal cycling, requiring tool steels such as H11.

On the other hand, the inner core is not subjected to the same level of stress, so mild steel is sufficient.

Therefore, cost and output time can be significantly reduced while maintaining performance.

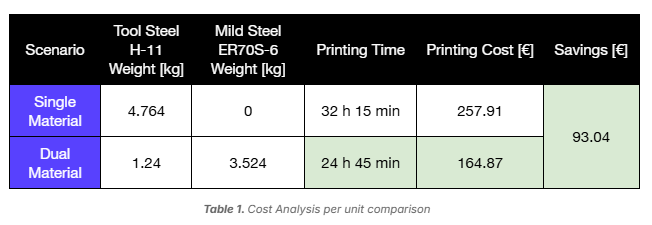

Please check the cost difference between printing the entire H11 and printing it using a heterogeneous material method combining ER70S-6 and H11 in the table below.

This heterogeneous material approach reduces tool steel usage by approximately 74% and reduces total output cost per part by more than 36%.

The output time is also reduced by approximately 23%, as the lamination speed of H11 is significantly lower than that of mild steel.

In other words, it does not end with simply reducing the use of expensive alloys.

The entire process Cost-effectiveness and time-efficiencyThis means that you can pull up both at the same time.

If savings of this magnitude can be achieved in actual production settings, it could be a turning point for the use of additive manufacturing.

In terms of productivity, the ER70S-6's lamination speed is up to 1.4kW with a blue laser. 423 g/hcan reach up to

Therefore, it is considered a particularly attractive material for manufacturing large parts, rapid prototyping, and economical repair work.

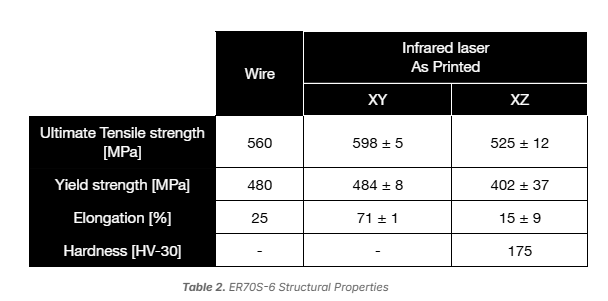

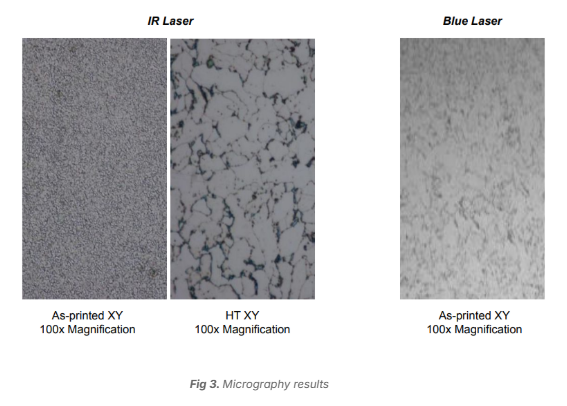

Microstructural analysis was performed by an external specialized laboratory, and 10×10×60 mm specimens were taken from the output block.

Preparation and analysis were conducted according to ASTM standards. The photos below show the results.

-

-

IR laser (infrared laser) : XY direction immediately after printing, XY direction after heat treatment

-

Blue laser : XY direction immediately after output

-

Yeongang is not limited to being used alone, A key role in hybrid manufacturing strategies.

Because it serves as a structural base, higher-performance alloys can be added to specific areas where they are needed.

This high versatility has made mild steel a very popular material in Meltio's metal 3D printing portfolio.

Especially for companies looking to introduce metal additive manufacturing, A practical and realistic starting pointThis is what is happening.

|Why Choose Meltio Steel

Meltio's ER70S-6 mild steel offers a reasonable balance of cost and performance, making it an optimal choice for additive manufacturing and hybrid applications.

today Mold with cooling channels (conformal cooling channels) We are also applying technology to development. W-LMD technology has excellent microstructure and 99.998% densityIt is possible to produce parts with properties that surpass those of castings and approach those of forgings.

|Cost-effective, high-performance solutions

Mild steel, especially ER70S-6, when combined with the right additive manufacturing strategy,

It shows that cost-effective materials can also deliver sufficiently high-performance results.

Because it can reduce the use of expensive tool steel and shorten production cycles,

For manufacturers, it offers a realistic alternative that can strike a balance between efficiency and durability.

As a result, Yeongang has become an important pillar of Meltio's material portfolio.

We help businesses adopt 3D printing more confidently and practically across industries.