Hello, this is HDC, a consulting firm specializing in AM solutions.

Additive manufacturing (AM) technology has been rapidly developing in recent years, attracting significant attention from both industry and research.

Technical characteristics such as process complexity and resolution are important factors in determining which additive manufacturing method to choose.

The reason why additive manufacturing can be utilized in various industrial fields today is because each technology has its own unique characteristics and various application possibilities.

Because each equipment user can choose a manufacturing process method that suits their individual needs.

Today, I'd like to talk about wire-arc additive manufacturing (WAAM), one of the many additive manufacturing technologies.

We will cover the concept, features, limitations, and various approaches to solving WAAM technology.

index

1. Introduction to WAAM, Powder Bed Fusion (PBF), and Meltio's Wire-Laser Metal Deposition (W-LMD) processes.

2. Wire-Arc Additive Manufacturing (WAAM): Limitations and Solutions

- High material deposition rate and low tolerance issues

- Unfavorable relationship between mechanical properties and heat input

- Problems with consumables during printing

- Challenges of Open Ecosystems: Lack of Trust

3. Conclusion

1. Introduction to WAAM, PBF, and W-LMD processes

AM technology can be broadly divided into two types depending on whether powder materials or wire materials are used.

Representative powder-based technologies include powder bed fusion (PBF) and laser-powder direct energy deposition (DED).

Among the wire-based technologies, the most commonly used in industrial settings are WAAM and W-LMD.

Powder Bed Fusion (PBF) process

The PBF process uses a laser or electron beam as a heat source to selectively heat and fuse metal powder particles, gradually forming the final part. This process melts metal powder particles one by one to create the desired shape.

Wire-Arc Additive Manufacturing (WAAM) process

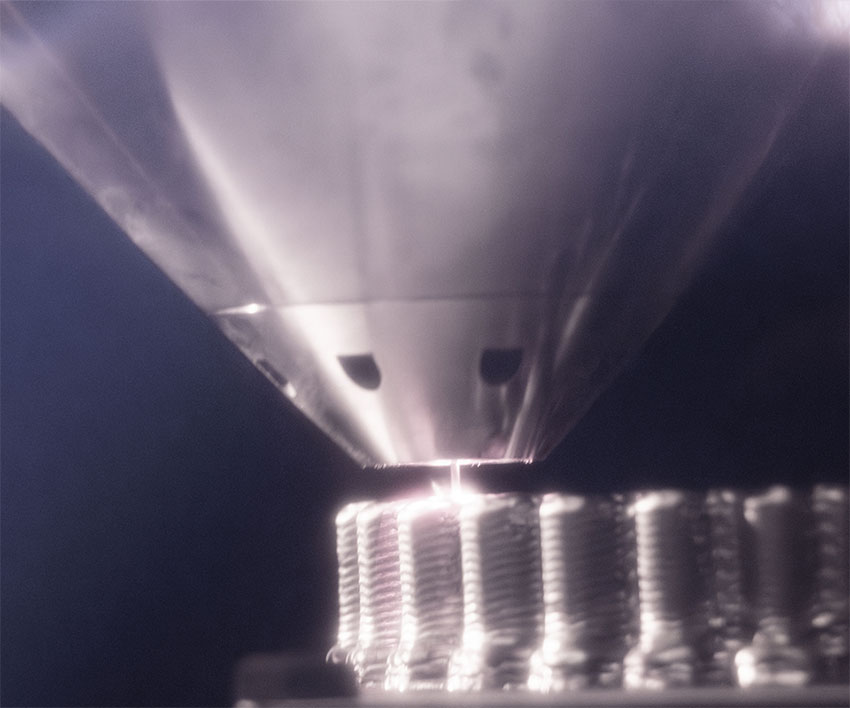

In contrast, WAAM uses metal wire as a material and an electric arc as a heat source, similar to a welding process. The electric arc melts the metal wire and deposits it layer by layer, forming a structure on a build plate or existing component.

The WAAM process uses inert gases to prevent oxidation and control the properties of the metal, which plays a crucial role in welding.

Additive manufacturing materials, utilizing metal wire, can be used to incrementally complete structures or repair existing parts. However, post-processing may be required to ensure more precise and smooth quality. CNC machining or surface polishing enhances surface precision, and heat treatment is used to ensure that printed parts are free of residual stress.

One such DED technology, the W-LMD process, uses multiple laser beams to precisely melt and deposit metal wires onto a build platform.

The most significant feature of W-LMD technology is its ability to concentrate heat in a very narrow area.

This minimizes the range of heat influence, improving the metallurgical properties of the final product. The resulting parts boast exceptional strength, uniformity, and overall quality.

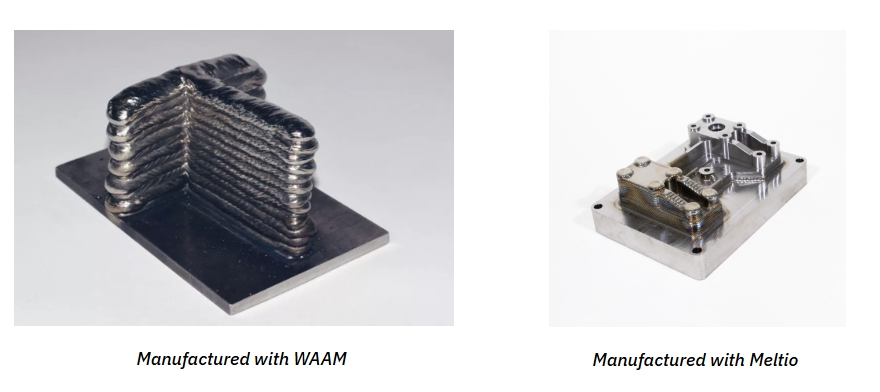

In particular, the WAAM process is advantageous for manufacturing large metal structures and has the advantage of fast production speed, but there are areas where improvement is needed in terms of surface precision and heat influence management.

In comparison, Meltio's W-LMD technology utilizes multiple laser beams to focus heat in a very narrow area, minimizing thermal effects and significantly improving the physical properties of the metal. This enables the production of parts with superior strength, uniformity, and surface quality.

Next, we'll examine the challenges WAAM technology faces and explore how Meltio technology can effectively address them.

2. Wire-Arc Additive Manufacturing (WAAM): Limitations and Solutions

WAAM is a 3D printing process that uses metal wire as a raw material. It uses a similar principle to traditional welding, where the metal wire is fed into the machine and an electric arc is used to melt and layer the wire.

Most of the defects that can occur in the WAAM process are related to parameters such as power, lamination speed, wire feed speed, and material selection.

In particular, WAAM can create small holes, voids, or pores throughout the structure.

Meltio's advanced technology complements WAAM's weaknesses, providing a solution that addresses complex manufacturing needs with greater precision and efficiency.

① High material deposition rate and low tolerance issues

The WAAM process has the advantage of being able to rapidly produce large structures, but it has some difficulties in implementing complex shapes or detailed structures.

While high material deposition rates make it advantageous for producing large parts, they can result in a rough surface finish, reduced precision when creating detailed internal structures, and tedious post-processing when large amounts of laminated metal are involved. Furthermore, the need to remove unnecessary material can lead to material waste. Meltio's W-LMD technology, on the other hand, excels at creating complex, intricate geometries.

While manufacturing speeds may be slower than WAAM, it produces parts close to their final shape (Near-Net-Shape), reducing post-processing and unnecessary material waste. This results in improved precision and quality of the final part, and makes complex designs easier to achieve.

② Unfavorable correlation between mechanical properties and heat input

The WAAM process often involves long exposures to heat due to its high energy input.

This high heat input can increase the grain size of the metal structure, negatively affecting the material properties or final accuracy of the part.

Also, to avoid these problems, the cooling time between layers must be set long, so the actual lamination speed may also be slow.

Meltio's W-LMD technology achieves a manufacturing process with lower energy input, resulting in less thermal distortion and a finer, more uniform metal structure compared to WAAM. This is a significant advantage, as the overall temperature of the part is lowered during manufacturing, resulting in higher quality and precision.

Additionally, when using multiple materials together, the dilution effect increases. This can be particularly detrimental in repair work.

*When using various metal materials together, the properties of the metals may change as they mix with each other.

This phenomenon is called dilution, and it can cause problems where metals mix with each other, weakening the desired properties.

TIP: If you're curious about how well Meltio technology dilutes, check out the Inconel 625 and H11 datasheets!

③ Consumables usage and replacement cycle during printing

The WAAM process often involves long exposures to heat due to its high energy input.

This requires periodic replacement of some parts, particularly consumables such as contact tips and nozzles, and consumable management is crucial for achieving consistent performance.

Key components, such as the contact tip, nozzle, and diffuser, can wear or become contaminated over time, degrading performance. Therefore, regular inspection and, if necessary, replacement are essential to maintain optimal performance.

Typically, contact tips need to be replaced after about 10 to 15 hours of use, and nozzles can be used for about 25 to 30 hours depending on the material and type used.

Replacing consumables in this way maintains weld quality, prevents defects, and extends equipment life, resulting in more efficient and reliable results.

On the other hand, the nozzle of Meltio W-LMD technology using laser heat source is an important part, but is usually about 336 hours It can continue printing for a long time, so the replacement cycle is much longer.

TIP: To maintain consistent equipment performance, it is important to prepare for replacement of consumables in advance and maintain optimal condition through regular inspection.

④ Challenges of independent configuration systems: ensuring stability

In the case of a typical WAAM technology system, the robot arm, print head, slicer software, and material must be purchased separately and assembled.

Meltio is here to solve these problems Fully integrated solutionIt provides.

The Meltio package includes the robot cell, software, continuously developed materials, and robot arm in one package, so it can be used right away without any separate configuration. Thanks to the integrated system, choosing Meltio allows you to verify and solve various problems in advance.

This prevents defects that can occur during lamination, such as gaps or small holes (bubbles), and reduces difficulties that can arise in the early stages due to compatibility issues between individual components, as with other technologies.

Additionally, Meltio's user-friendly design allows customers to quickly integrate the technology into their manufacturing processes.

In fact, some customers are using new materials within a weekThere are also cases where testing has begun, which clearly demonstrates the high usability and adaptability of the Meltio system.

The wires used in Meltio equipment undergo rigorous testing and verification to ensure optimal quality and reliability.

In particular, since it uses wires optimized for Meltio technology, you can expect stable and consistent performance without complex adjustments.

Meltio provides customers with reliable solutions, along with proven wires to maximize the performance of their equipment.

Furthermore, we are a company that continuously researches optimal conditions to maintain excellent quality in various usage environments, striving to provide our customers with reliable performance and superior quality, enabling them to experience a more efficient work environment.

3. Conclusion

WAAM technology has been widely used in industrial fields for a long time, and its value and usability have been clearly proven.

Although it still plays an important role in many fields, especially because it shows excellent performance in the production of large structures, it is true that it has some limitations in terms of manufacturing efficiency and precision compared to laser-based technology.

WAAM is advantageous for fast deposition speeds and large part production, but post-processing can be cumbersome for tasks requiring surface quality or precision.

Additional efforts are required in terms of component completion and quality control.

W-LMD technology increases productivity by streamlining the workflow while minimizing common problems that may occur.

The simplified manufacturing process should further improve the quality and structural integrity of the final product, as it helps reduce material waste and repair costs.

For those who need solutions HDC is Meltio's W-LMD solutionI suggest.

With Meltio, you can experience faster, more reliable, and better manufacturing performance and efficiency across a wide range of industries.