Hello, this is HDC.

Today, we'd like to introduce a metal additive manufacturing (3D printing) project conducted by researchers at the Bordeaux Institute of Mechanical Engineering (I2M) and the BUT program at the University of Bordeaux, France. They are researching innovative manufacturing technologies, focusing on metal 3D printing processes, and are consistently striving to improve efficiency and reliability in industrial settings.

The core goal of this project is Achieving the same performance with less materialThe challenge was to design and build a lightweight tripod suitable for aerospace applications, exploring ways to maximize performance with minimal resources.

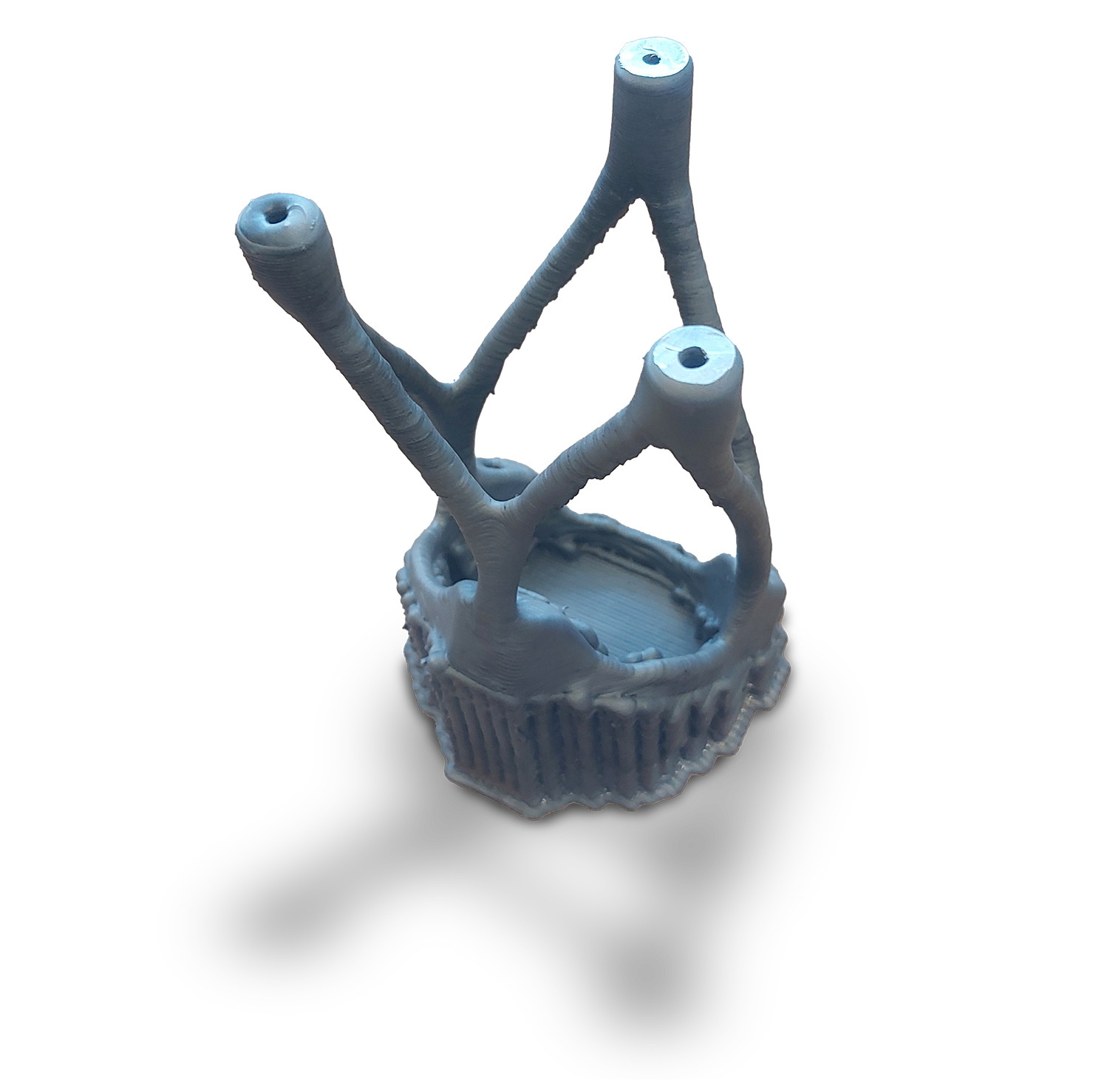

“Light but strong” — the power of topology optimization

The first approach to the project was topology optimization It was.

The key was to boldly remove unnecessary material while maintaining the strength and essential mechanical performance of the part.

This approach is particularly effective in aerospace applications, as weight reduction naturally improves fuel efficiency and overall performance.

Additive manufacturing technology, which allows for the free implementation of complex shapes, has made optimized designs that were previously difficult to achieve possible.

Researchers at the Bordeaux Institute of Mechanical Engineering (I2M) specialize in additive manufacturing (AM), particularly metal 3D printing processes. Faculty at the University of Bordeaux's BUT program focus on design and manufacturing processes.

Their core goals are to implement robust process control and develop innovative approaches to learning and manufacturing. They are actively conducting research focused on metal additive manufacturing systems and are continuously striving to improve efficiency and reliability across a wide range of industries.

Same performance with less material

The goal of this project was to design and manufacture a lightweight tripod suitable for aerospace applications.

The goal was to dramatically reduce material usage while maintaining essential mechanical performance.

To this end, we design complex shapes using topology optimization algorithms.

Optimized to maintain the strength of the part while removing unnecessary material from non-critical areas.

This approach is highly effective in the aerospace industry, where weight savings directly translate into improved fuel efficiency and performance.

How did Meltio's W-LMD contribute?

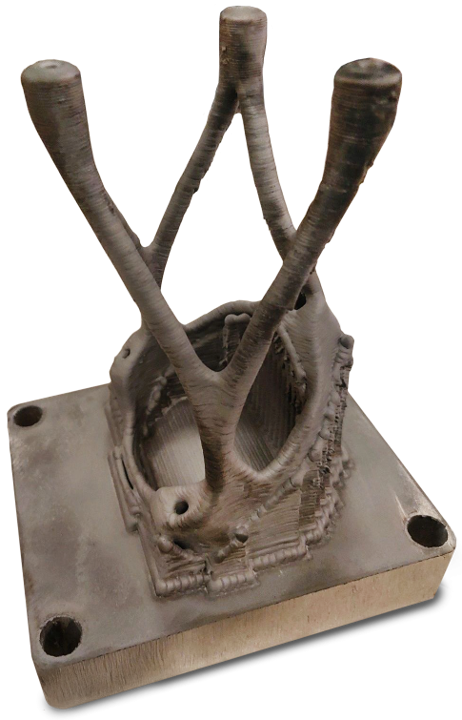

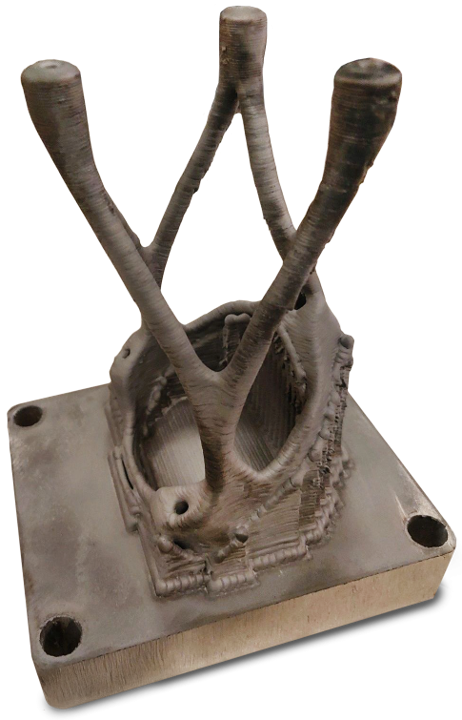

Meltio's project Wire-Laser Metal 3D Printing Technology (W-LMD) This played a big role.

Especially the newly introduced Meltio M600 equipmentis a high quality metal part economically productiveIt got attention because it could be done.

- Increase material utilization and reduce costs by using wire raw materials.

- The working environment is safer and cleaner than powder method.

- Provides high lamination speed and excellent mechanical properties

In addition, we monitor the surface processing status in real time during the process and meticulously analyze the microstructure quality after output to enhance the level of completion.

Additionally, the hybrid wire-laser method offers excellent mechanical properties and high deposition rates, making it particularly suitable for industrial applications.

The research team is also improving technological perfection by conducting in-situ monitoring of surface processing and post-mortem analysis of subsequent microstructure quality.

Optimized part shape (topology)

What are the project results?

35% reduction in material usage / 10.5 times reduction in production time

System: Meltio M600

The Meltio M600 supports the efficient production of complex-shaped parts based on robust material performance.

Application Areas: Research and Development & Aerospace

Meltio meets Class 1 laser safety standards, ensuring worker safety from laser exposure.

Material: Stainless steel

Wire feedstock has proven to be a less expensive and safer alternative to powder-based methods in the workplace.

Printing time:

The wire-stacked design reduces smoke and contaminants, keeping your workspace cleaner and safer without the need for complex filtering devices.

Meltio's introduction to R&D and its significance beyond that

This project enabled the Meltio platform to expand beyond simply improving manufacturing processes to researching new shapes and material combinations.

Representative examples include the development of functional gradient materials and lightweight structures.

Ultimately, the combination of additive manufacturing and topology optimization has opened up new possibilities in aerospace,

It has shown the potential to lead to the development of more efficient and high-performance components.

We expect that the value of additive manufacturing technology will continue to shine through these innovative examples in the future.