Hello, this is HDC.

Today, additive manufacturing technologies, particularly Wire Arc Additive Manufacturing (WAAM), can solve supply chain problems.

Let us show you how we can help solve delivery delays and productivity issues.

Let's take a look at how the industry is solving its challenges, focusing on an interview with Gijs van der Velden, CEO of MX3D.

Robotic WAAM is a high-quality,

A solution suitable for in-house production.

How long will it take to deliver urgently needed engineering products such as valves, pumps, and pressure vessels?

Fittings or flanges made of special alloys? Orders? Months?

These long lead times are often taken for granted, but they can be a huge headache in the event of unexpected maintenance or repairs.

It can even lead to loss of sales.

In this situation, WAAM (Wire Arc Additive Manufacturing) can be an effective solution for shortening lead times.

Gijs van der Velden, CEO of MX3D, emphasizes that WAAM is a solution that can solve supply chain problems.

A familiar yet new technology, WAAM

WAAM is not some unproven technology that just came out of a modern lab.

It is a reliable additive manufacturing (AM) technology that has been used in various industries for a long time since it was first patented in 1920.

Basically, it is a form of arc welding and is a process already familiar to metalworking industries around the world.

There are two reasons why WAAM has been attracting attention recently.

First, the development of CAD/CAM software.

Second, the emergence of advanced robotic systems.

Thanks to this, today's WAAM systems can output metal parts that are almost as close to their final shape as possible.

It is positioned as a solution that can revolutionize everything from cost and delivery times to material efficiency and local, on-demand production.

MX3D is leading the adoption of WAAM in various industries, mainly in the Netherlands.

Representative examples include the 12-meter-long stainless steel bridge installed on the Amsterdam canals, DED parts for BMW,

Research on 3D printing of carbon steel pipe connectors with Japan's JGC.

▶ Firm positioning toward the energy industry

MX3D's core target is the energy industry.

Because WAAM has a clear advantage in special materials and low-volume production parts.

For example, materials such as duplex stainless steel and high-corrosion-resistant alloys can be produced quickly.

These materials are very difficult and expensive to cast.

Van der Velden says, “Thanks to WAAM, our customers can quickly obtain the parts they need,

“This will bring about a huge change to the entire supply chain,” he explains.

▶ A shift in perception in the valve industry

MX3D participated in the Valve World Expo & Conference to understand the needs of the valve and flow control industry.

The economic benefits of WAAM were positively assessed in this position.

“People were very surprised that the WAAM system could print a 100kg valve body in a few days.

Of course, a final finishing treatment is required, but this is the same process as machining a casting.”

Van der Velden adds:

In emergency production, expensive materials such as duplex stainless steel are discarded as waste at up to 80% during processing.

WAAM can reduce this waste and even cut energy consumption and emissions.

The valve industry in particular has long taken long lead times for granted.

Thanks to WAAM, we've seen that "order a valve and get it in a matter of weeks" can become the new standard.

▶ WAAM's target market

Changes in the subject of production and independence

Every year, MX3D creates unique WAAM products that push the boundaries of technology.

This 3D-printed stainless steel bridge has been installed on one of Amsterdam's famous canals.

There is also growing interest from companies looking to produce their own parts without relying on OEMs (original equipment manufacturers).

This is especially true in industries where long lead times are critical.

Van der Velden said

“

Having a WAAM system in place allows businesses to gain a more independent position,

It can completely change the way your supply chain operates.

“

He emphasizes that.

End users who hold intellectual property rights (IPR) can also achieve self-sufficient manufacturing through WAAM.

WAAM Quality and Standards

WAAM already meets major international standards such as API-20S, DNV-BT-203 and ASME Section IX.

Standardization for 3D printing processes is actively underway, and it is expected to be equivalent to or better than cast products in terms of pressure retention capacity, material properties, and quality.

It's showing better results.

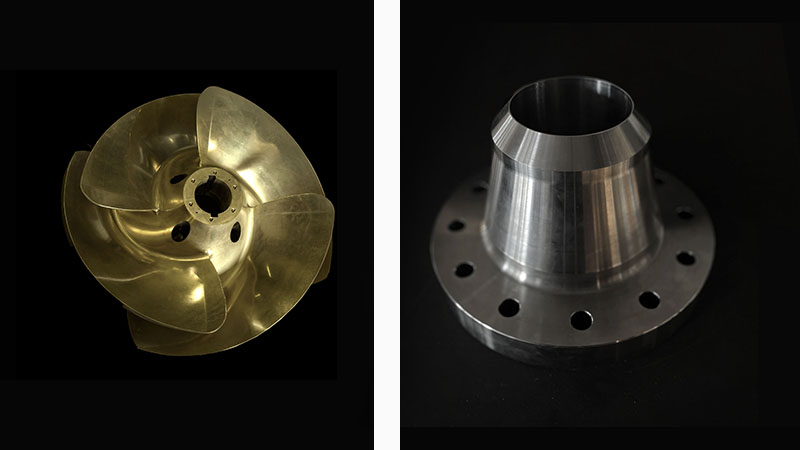

Unique piping and pump components like these can also be manufactured quickly, including using special alloys.

▶ Surface quality and actual application cases

WAAM output has fine grain due to the nature of the welding process, but this is similar to that of a casting.

If necessary, you can obtain a smooth surface by machining only 0.5 to 1.5 mm.

Although the surface quality is a bit rougher than the Laser DED method, WAAM is more than 10 times faster in terms of productivity.

For customers where delivery is critical, WAAM is a better solution.

|

|

The WAAM system offers businesses greater independence and can revolutionize the way they operate their supply chains.

Gijs Van der Velden:

“Our technology empowers customers to rapidly produce parts made from materials that are difficult to obtain through casting, such as duplex stainless steel and advanced alloys.”

▶ MX3D's approach

MX3D designs custom WAAM systems and also manufactures components and prototypes in-house.

We ensure safety and consistency through quality monitoring and data analysis based on multiple sensors.

We develop innovative prototypes every year to discover new business cases.

“We are always ready to talk to our customers to solve their problems,” said Van der Velden.

“If you need a perfect finish, a custom solution is the way to go. If speed is key, WAAM is the way to go,” he says.

Source: Stainless Steel World, “How WAAM could reduce supply chain blockages”

(See original text: https://stainless-steel-world.net/how-waam-could-reduce-supply-chain-blockages/)