Hello, this is HDC.

today Large-Factory Additive Manufacturing (LFAM) MicrofactoriesWe present an interesting case study of how the manufacturing industry is changing.

especially Automation, flexibility, and sustainabilityFocusing on the keyword CEAD, Haddy, Al Seer Marine Let's take a look at how innovative companies are transforming industries.

The Future of Manufacturing: Microfactories and Lights-Out Production

As digital transformation accelerates, large-scale additive manufacturing (LFAM) technologies are rapidly replacing traditional manufacturing methods.

At the center of this change is LFAM MicrofactoryThere is.

Microfactories are industry experts Peter Wells and Paul NieuwenhuisA concept first proposed by

Small to medium-sized modular manufacturing facilities that integrate automation and advanced technologies to maximize operational efficiency.

These microfactories respond to the changing needs of the market, overcome the limitations of traditional manufacturing, and lead to sustainable growth.

It is positioned as a key element.

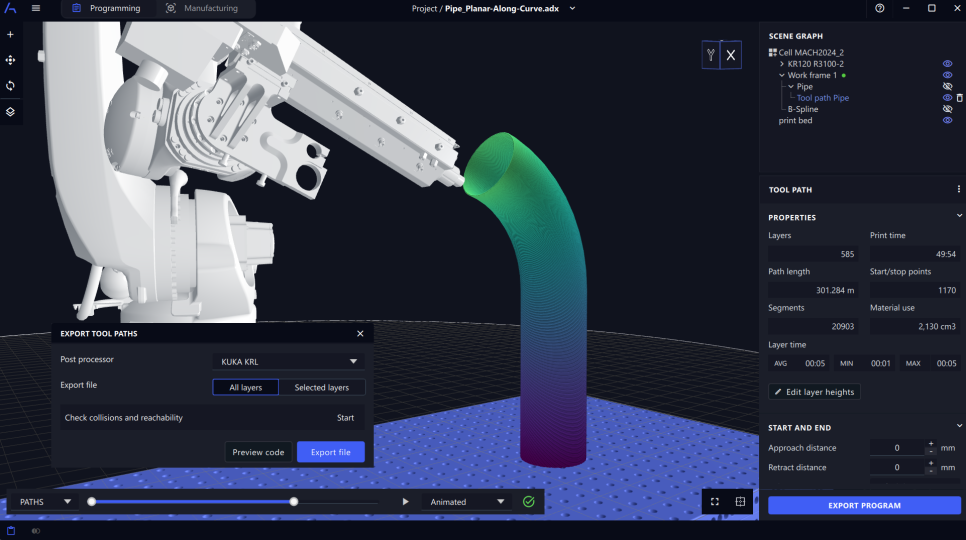

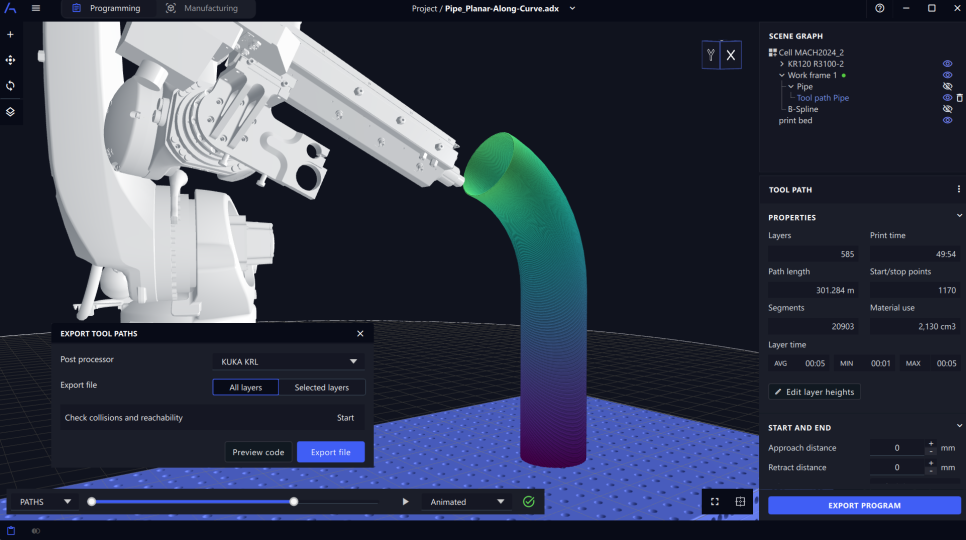

CEAD B.V., headquartered in Delft, Netherlands, and CEAD Group Inc., located in Detroit,

We are leading the development of automated LFAM solutions and microfactories for the production of large composite components.

▶ Solutions to the shortage of skilled workers and rising costs

The manufacturing industry faces significant challenges: a shortage of skilled workers and persistently rising costs.

In particular, traditional manufacturing methods require molds, jigs, and special tools, and the number of highly skilled workers capable of designing and manufacturing these is decreasing.

When product designs change, new tooling is required, which can take more time and money.

CEAD's LFAM Microfactoryis robot-based FlexbotWe solve these problems through:

Direct 3D printing and CNC post-processing based on digital CAD models are performed, reducing intermediate processes and increasing production speed.

This allows for faster implementation of design modifications and significantly shortens the time it takes to launch a product.

▶ Intelligent production based on Industry 4.0

CEAD is Automation, IoT, AI, and machine learning By integrating Industry 4.0 technologies, we have implemented a data-driven system that operates autonomously with minimal human intervention.

Self-developed Data Logging PlatformWe perform real-time monitoring and data analysis through

Reduce downtime and maximize operational efficiency with predictive maintenance.

This allows us to meet mass production demands without high labor costs and maximize production uptime.

▶ Scalability to flexibly respond to market demand

LFAM microfactories are space-efficient and can be rapidly expanded to meet market demand.

A Florida-based 3D-printed furniture manufacturer Haddyis a case that illustrates this point well.

Haddy in 18 months Two Flexbots with a 4x2m areaStarting from, now Operate 8 Flexbots in a 14x2m areaand expanded its production capacity.

one side, Al Seer MarineThe system uses a custom Flexbot system that places two robotic arms on a 40-meter track.

They 3D printed the world's first electric Abra (a traditional wooden boat) and also built a 12-meter-long water taxi in just six days.

The modular Flexbot allows customers to configure only the features they need, avoiding unnecessary investments and providing a flexible solution that maintains future scalability.

▶ Think Globally, Produce Locally – On-Demand Production

The existing furniture industry was slow and inefficient due to third-party reliance, remote manufacturing, and mass imports, and also had serious carbon emissions problems.

Haddy has installed Flexbot microfactories in key locations around the world. Locally focused productionis being implemented.

This has reduced logistics costs and lead times, and dramatically increased production and delivery speed.

Fab.pub also offers a robotic arm with integrated CEAD technology. container We are operating a mobile factory franchise model that is installed inside.

Flexcube is container-mounted as a finished product, enabling rapid on-site installation and operation.

This approach has great advantages, especially in fields that require rapid response, such as the defense industry.

▶ The Path to Sustainable Manufacturing

LFAM Microfactory is Thermoplastic pellet materialMainly used to reduce raw material procurement risk,

Without the need to hold large quantities of molds or stock parts. On-demand productionThis is possible.

We analyze efficiency through data logging, reduce resource waste through predictive maintenance, and recycle unusable materials and discarded parts to achieve circular manufacturing.

Haddy is NFC tagWe operate a closed-loop system that attaches parts to customers so they can be returned after use and reprocessed into new furniture.

▶ CEAD's Future: MAC, a Maritime Industry Innovation Hub

CEAD recently Maritime Application Center (MAC) Established,

We operate as an innovation hub integrating materials research and software development for the marine industry.

This increases the operational efficiency of automated LFAM, maintains competitiveness in a rapidly changing manufacturing environment, and continues sustainable production.