Hello, this is HDC.

Today, Gary Mécanique, a family-owned business in France with over 60 years of experience in precision machining, Robot-based metal additive manufacturingWe would like to introduce how we are overcoming the limitations of existing manufacturing methods.

French family-owned company rewrites the future of metal manufacturing.

Founded in 1962, Gary Mécanique, a family-owned business based in Roubaix, northern France, has accumulated expertise in precision machining for over 60 years. Since the early 1970s, the company has been at the forefront of technological innovation, pioneering CNC machining and now offers high-precision 5-axis machining.

Recently Gary Mécanique Meltio's wire-laser-based Directed Energy Deposition (DED) We're integrating technology with robotics to pioneer new metal manufacturing methods. This technology enables the more flexible and precise manufacturing and repair of large, complex metal parts.

▶ Complex and rapid production: a new standard demanded by the industry.

The industries Gary Mécanique serves, including defense, energy, automotive, and aerospace, are increasingly demanding the production of complex and larger parts, faster.

However, conventional methods such as casting and welding take a long time, are expensive, and offer little design freedom.

It is at this point that metal 3D printing, and Meltio in particular, comes into play. Wire-Laser DED Technology is becoming an effective solution.

▶ It's clear why Gary Mécanique chose Meltio

- Large parts can be manufactured without traditional casting methods.

- Near-Net-Shape Precision Manufacturing to Reduce Machining Processes

- An efficient repair and rework environment that can be handled directly in-house

- Flexible response to various shapes and materials without mold replacement

“

Freedom of material and shape, captured simultaneously

“

Gary Mécanique has built a machine that can control up to eight axes by linking a Fanuc 6-axis robot and a 2-axis positioner to a Meltio engine.

Not only 3-axis and 5-axis fixed positioning, but also 5-axis continuous machining is possible, so even complex shapes can be printed without problems.

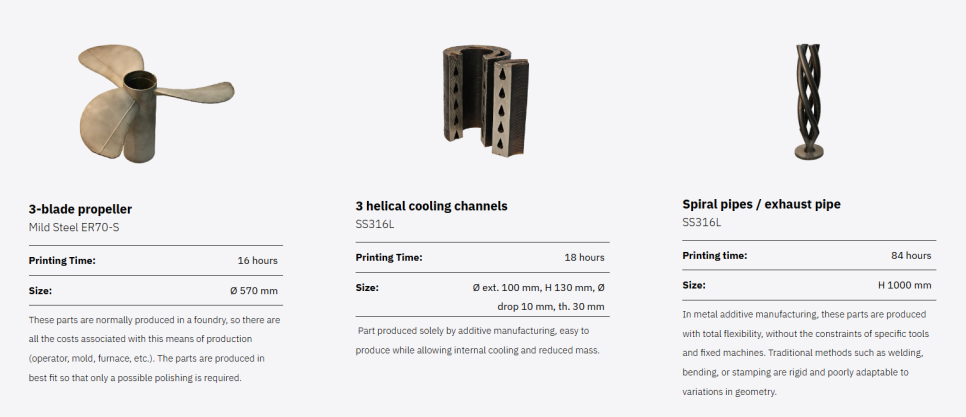

- Applicable materials: Compatible with various wires such as 316L stainless steel and ER70S6

- Size correspondence: Maximum diameter 2m, weight 2 tons

- Scope of application: Wide range of applications including finished product manufacturing, hybrid production, and parts repair.

▶ Production methods changed by Meltio technology

Meltio's Wire-Laser Additive Manufacturing (WLAM) technology is based on readily available metal wire.

It can use not only 316L and ER70S6, but also Inconel, titanium, and even gold, making it possible to produce parts that were previously impossible with conventional processes.

✔️ Maximize production flexibility

✔️ Minimize waste

✔️ Can be produced immediately when needed

✔️ Improved process efficiency

✔️ Easy quality verification

✔️ Compatible with various materials

▶ Beyond production, repairs are now possible.

One of the biggest changes that Gary Mécanique has seen with the introduction of Meltio is

It is now possible to rework the existing parts by placing them back on the equipment.

By reinforcing only the necessary parts without having to rebuild the entire thing,

We've reduced costs, shortened lead times, and even implemented more environmentally friendly manufacturing methods.

Additionally, Meltio's close-range shape output capabilities significantly reduce processing time and material waste.

▶ Beyond Technology: The Future of Manufacturing We Desire

Since the introduction of Meltio's robot-based wire-laser technology,

Gary Mécanique is not just about technological change. A new standard for manufacturingis being presented.

By combining the latest AM technology with existing processing techniques, we have created an agile, precise, and scalable production environment.