Hello, this is HDC, a consulting firm specializing in AM solutions.

Today, we'll explore the advantages of Spain's Meltio's WLMD process compared to powder-based additive manufacturing (AM) technologies.

Powder-based technology has the advantages of high resolution and wide range of materials, but it also has its challenges.

In particular, we will discuss the limitations and potential drawbacks that can be encountered when using powder-based AM technology.

A proper understanding of these aspects is essential for evaluating the true potential of the powder AM process and optimizing its performance in real-world applications.

By comparing the Meltio process and powder-based technology, we clearly understand the advantages and disadvantages of each.

Let's learn together so you can make better choices in your manufacturing field!

index

- Powder-based AM technologies: PBF and powder DED

- Wire + Laser: A New DED Combination

- Benefits of Meltio's Wire-Based 3D Printing (WLMD) Process

- Additional Benefits of Meltio WLMD

- conclusion

1. Powder-based AM technologies: PBF and powder DED

Among powder-based additive manufacturing (AM) technologies, the processes that utilize lasers include Powder Bed Fusion (PBF) and

Powder DED (Directed Energy Deposition) is a representative example.

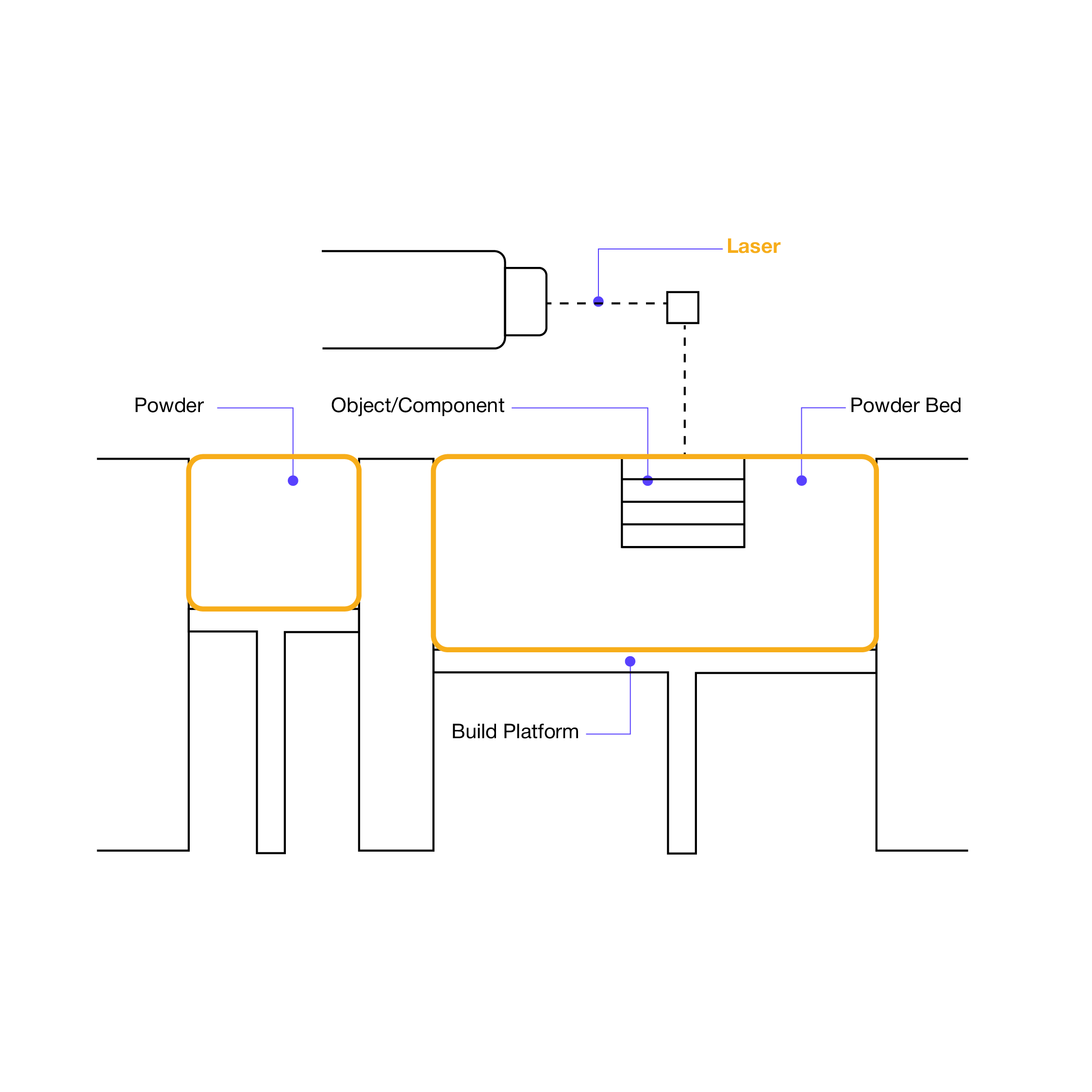

Powder Bed Fusion (PBF)

PBF is one of the most widely used additive manufacturing processes, primarily used to create 3D objects in the engineering and biomedical fields.

The greatest advantage of this process is that it can be layered using a single material, enabling the creation of complex shapes and custom designs, enabling the production of parts optimized for specific industry needs.

Because PBF can realize complex structures with high resolution and precision, it is widely used in aerospace, medical device, and automotive applications that require sophisticated components. However, the powder-based nature of PBF also presents practical limitations, such as dust management, material waste, and maintenance costs.

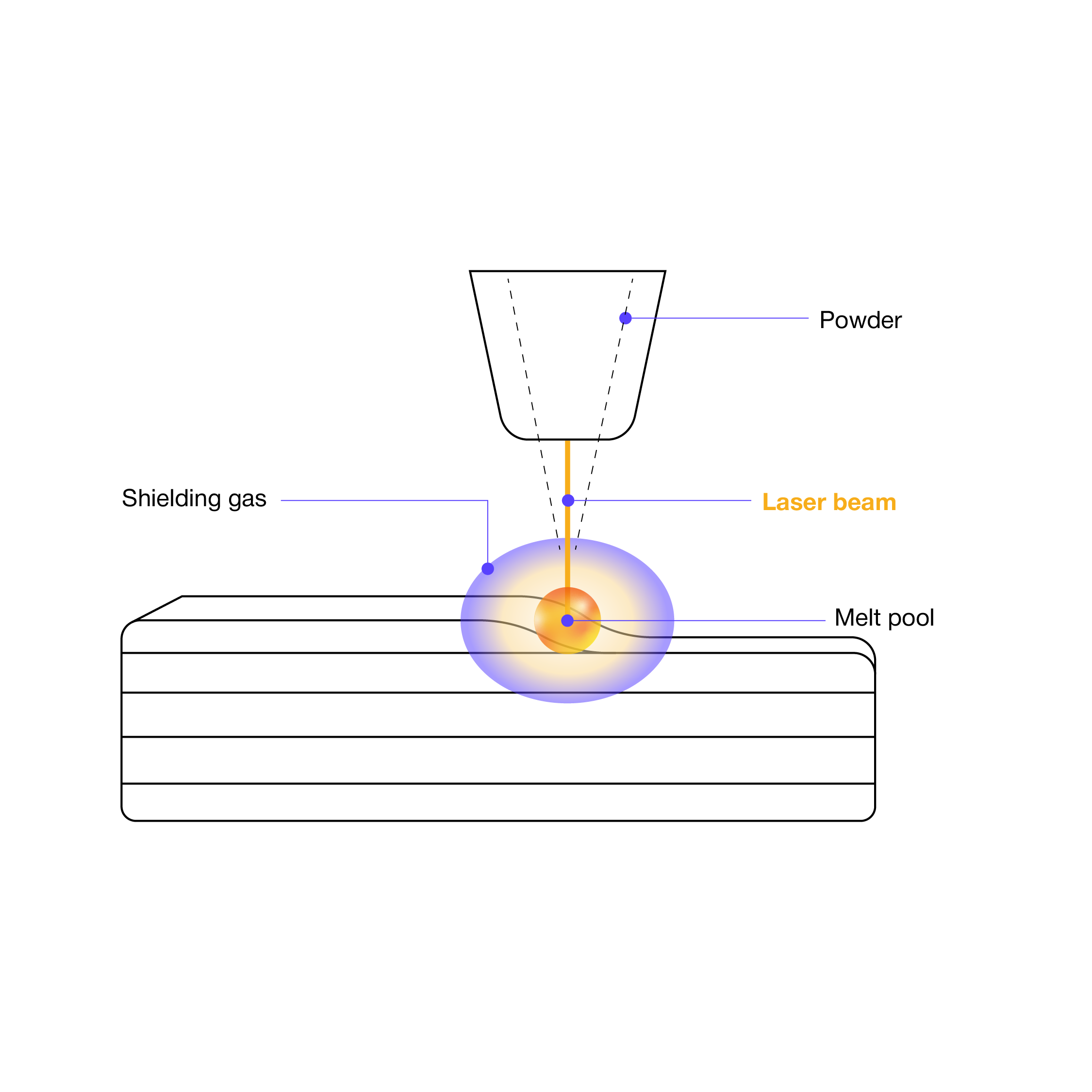

Powder DED (Directed Energy Deposition)

Powder DED (Direct Energy Deposition) technology is one of the additive manufacturing (AM) technologies that has been utilized since the earliest times.

It is well known that its utility is very high. This process Raw materials are supplied directly to the lamination area and immediately melted by laser.It uses a method where the laminating head moves slowly to create layers. Form one by oneand the molten material naturally combines with the previously laminated layers. sturdy structureIt creates,

Continuously spraying powder through a nozzle at the focus point of a high-power laserThe heat from the laser melts the metal powder to form a molten pool, and this molten material Moved by motion control systemIt is layered in free space while being built up.

This process The shape of the part is gradually revealed as each layer is added.It has the advantage of enabling visual monitoring as it can be checked in real time. However, powder-based DED processes also have some limitations.

first of all, Since powder is continuously sprayed, there is a problem of flying and waste of materials.may occur and the quality may not be uniform. Difficult to maintainThere is this. Also, Surface roughness problemPost-processing is often necessary, which can reduce process efficiency.

To overcome the limitations of this powder-based DED technology, Meltio's wire-based 3D printing processNow, let's see how this wire-based technology differentiates itself from powder DED technology.

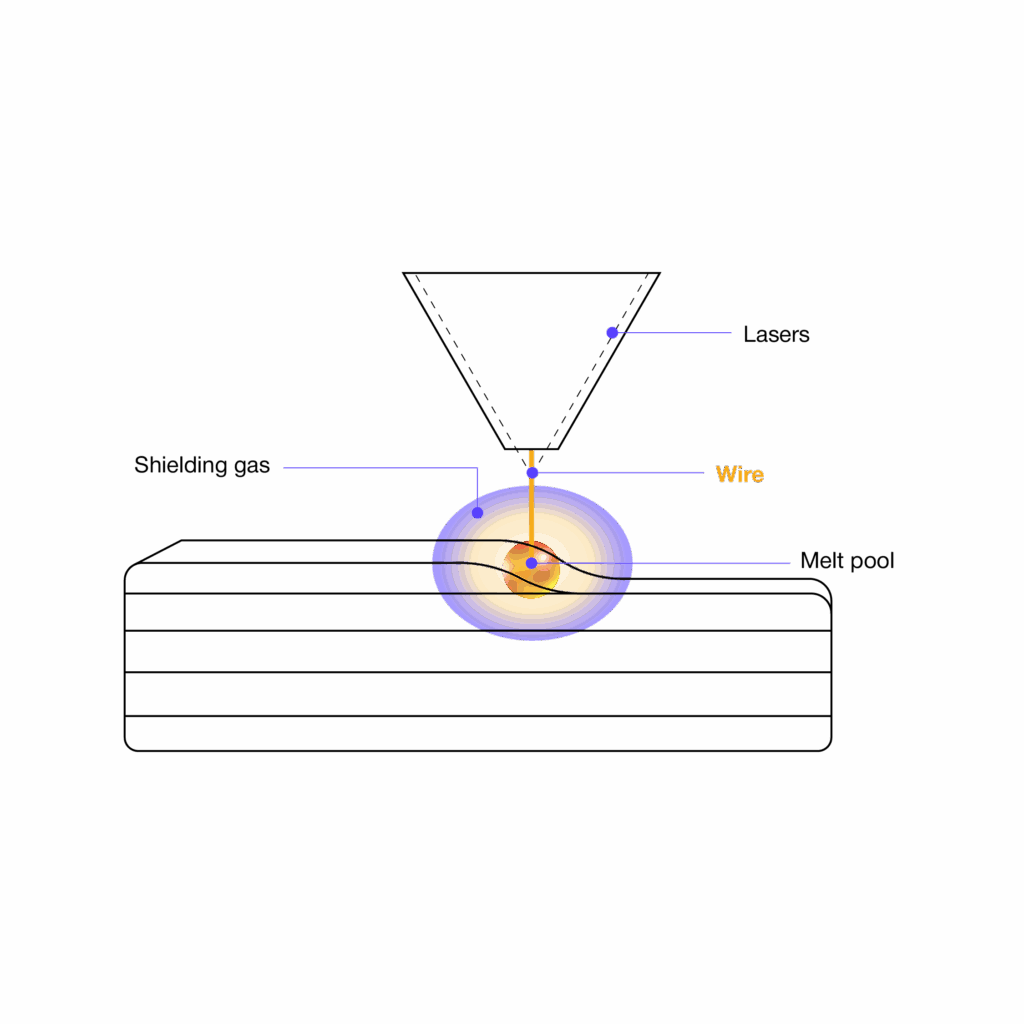

2. Wire + Laser: New DED Combination

Direct Energy Deposition (DED) is a type of additive manufacturing (AM) technology that uses a concentrated heat source to melt and deposit raw materials.

DED in metal applications

DED technology is used in the production of metal parts. The advantage of being able to produce large metal parts at high deposition rates.It has a much higher deposition rate than other AM methods such as Powder Bed Fusion (PBF). A representative method among powder-based DED technologies is Laser Powder-Directed Energy Deposition (LP-DED), which has been used for many years. cladding It has been widely used in the process.

Wire + Laser Combination: A New Additive Method

With the recent development of additive manufacturing technology, DED combination using wire as raw material and laser as energy sourceThis has appeared.

This is a distinct approach from conventional powder-based DED, offering several advantages in terms of deposition speed and material utilization.

Although DED technology itself has been used in various industries for many years, The combination of wire feedstock and laser energy source introduced by Meltio is a relatively new technology.Due to its innovation and practicality, it is attracting attention in various industries.

Now Meltio's Specific advantages of wire-based 3D printing processesLet's learn about it.

3. Benefits of Meltio's Wire-Based 3D Printing Process

Meltio's wire-based 3D printing process offers several unique and noteworthy advantages over conventional powder-based direct-deposition printing (DED). Here are some key reasons why this combination is considered innovative.

① Continuous Deposition Process

In wire-based DED processes, Continuous supply of wire feedstock for smooth, uninterrupted layer buildscan be implemented. This allows Increased production efficiencyAnd the production time is greatly reduced.

Additionally, there is no need for frequent interruptions or manual handling during the process. Process consistency and level of automationThis is a huge improvement.

② Suitable for manufacturing large parts (Large-Scale Applications)

Continuous supply and Characteristics that require less support structures Thanks to you Optimized for manufacturing large partsIt is done. These process characteristics are Manufacturing large industrial parts or structuresIt brings time and cost savings.

especially Fabrication of large metal structuresCompared to existing powder-based technologies Fast and efficient productionno see.

③ Material Waste Reduction

Wire-based additive manufacturing process Less material waste compared to using powder. so you only use as much wire as you need. There is almost no excess material generated Cost savings and Advantageous in terms of sustainabilitydo.

Thanks to these characteristics Eco-friendly manufacturing processIt is also evaluated as having high material utilization efficiency, which is a major advantage.

④ Cost-Effectiveness

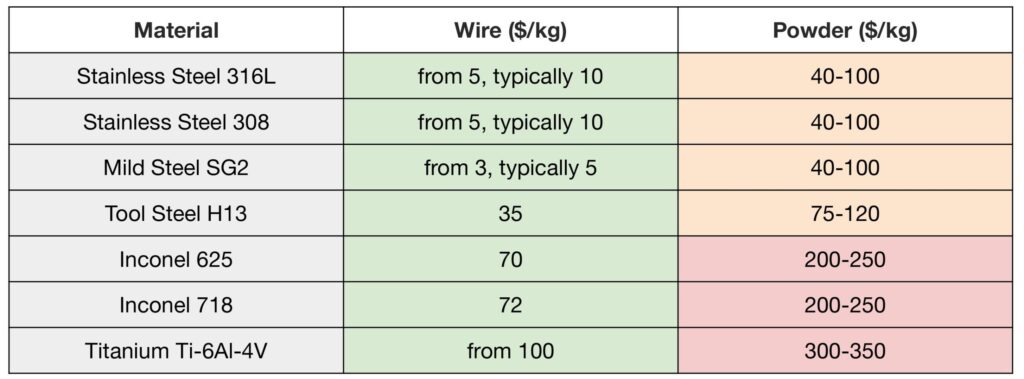

Wire feedstock is better than powder material. It is cost effective.

- Wire material is a common material already widely used in the welding industry.As such, it is easy to obtain and inexpensive.

- About $3.00 per poundWire prices starting from are generally Up to 10 times cheaper than expensive powder materials, and the difference is more pronounced in certain alloys.

- Simple and economical to produce and handleBecause of this, in the whole process Material cost reduction effectYou can enjoy it greatly.

⑤ Enhanced Productivity

Wire-based processes are particularly continuous lamination systemMore efficient and productive in wire feedstock Production without interruption as it is continuously suppliedThis is possible Minimize downtimedo Maximize outputto realize.

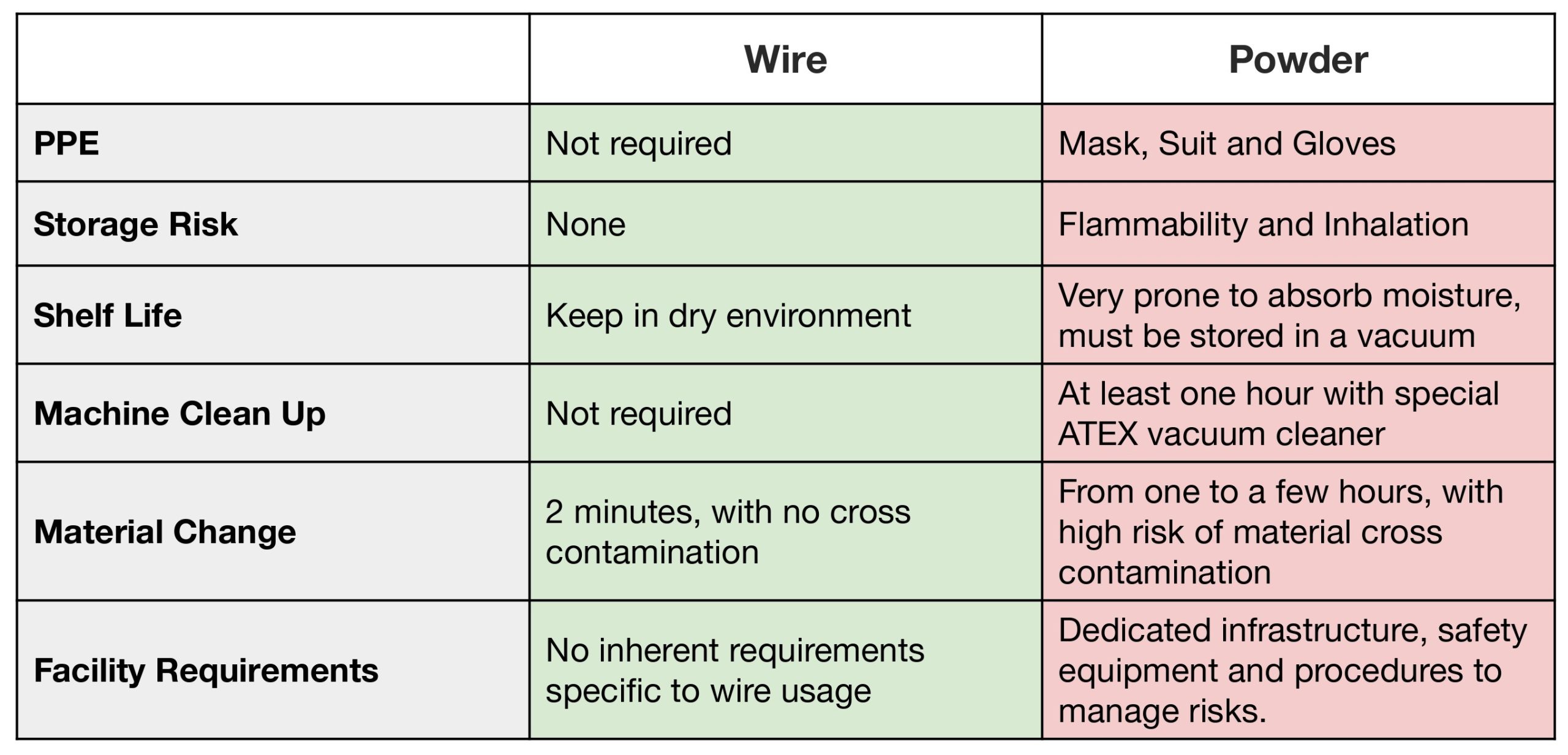

⑥ Reduced Need for Protective Equipment

Unlike powder-based additive manufacturing processes, wire-based methods Less protective equipment is needed as there is little risk of airborne particulate matter.Because of this Worker safety and comfortThis will significantly improve safety and reduce safety management costs.

⑦ Minimizing Facility Requirements

Wire-based additive manufacturing process Effective even in facilities with space constraints or workplaces with specific infrastructure requirementsno see. Simple handling of wire feedstock Thanks to this, there is no need for separate facility modification or complex equipment configuration. Cost-saving effectprovides.

⑧ Convenient Storage

Wire feedstock is Easy to store, unlike bulky and difficult to handle powder materialsThe wire is Takes up less space Easy to organize and manage Maximize storage space utilizationYou can do it.

⑨ Ease of inventory management

Wire feedstock is Store in a structured formBecause it becomes Easy inventory management and quantity trackingIt makes it easy to keep track of how much wire is left. Efficient material replenishment planThis is possible, unlike some powder materials. The shelf life is long There is no problem with long-term storage. The base process

⑩ Reduced Contamination Risk

The wire is Stored in a solid state and has little possibility of dispersing Between different materials Minimizes the risk of cross-contaminationOn the other hand, in powder-based processes, Possibility of contamination due to mixing or spillageThis high level of rigor requires strict cleaning procedures. This is a crucial advantage, as contamination can severely impact the microstructure and quality of the component.

⑪ Improved Handling and Transportation

Wire feedstock is supplied in a solid, tightly wound form for easy handling and transportation. wound on a spool or reel Easy to load into 3D printing systems.

⑫ Simplified Machine Clean-Up

Wire-based additive manufacturing processes are more cost-effective than powder-based processes. Easy machine cleaning due to less residueThere is almost no residue or dust. Reduce the burden of frequent cleaning and keep your workspace tidy.I can do it Efficient workflowSupports .

⑬ Ease of material change

Wire-based processes Material conversion is relatively simpleThis allows for easy replacement of various materials. Minimize downtimeAnd Dual material partsIna Various componentsIt is advantageous when manufacturing. Unlike powder-based processes, there is no need for complex cleaning or washing processes. Rapid material replacementThe fact that it is possible is a great strength.

⑭ Zero Material Waste

Meltio's Dual wire metal lamination processsilver Designed so that the wire enters the melt pool coaxiallyIt is done.

Through this 100% efficient use of materialsYou can do it.

On the other hand, powder-based processes Material waste rate ranges from 30% to 50% There are many cases where this happens, and there is a big difference in terms of economy and efficiency.

Pipe Manifold by DMZ Engineering

⑮ Enhanced Microstructure

Meltio's The laser process creates a very dense heat affected zone (HAZ).Thus, heat transfer to the lower layer of the molten pool or surrounding area is minimized.

Because of this The microstructure of the printed parts is more robust and uniform.Thus, superior quality in terms of strength and durability can be secured.

⑯ Controlled Process

Meltio's LMD process is Precise control to ensure that the wire enters the molten pool coaxiallydo.

The wire is Melting at the point of contact with the substrateAnd because it melts regardless of the material flow, Stable and controlled processThis is possible.

also, Advanced feedback systemBy implementing Maintain consistent process qualityYou can do it.

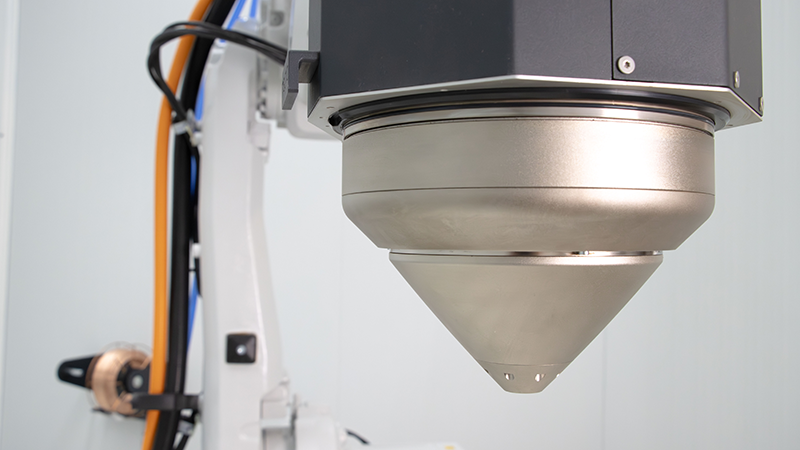

⑰ Meltio's Deposition Head

Meltio's stacking head is Coaxial wire supply designFeaturing, Configure the wire to enter the center of the molten poolIt is done.

This structure is Consistent print quality in all directions, and guarantees Long service life due to the laser's low optical densitycan be maintained.

Thanks to this, along with high quality printing, Extend equipment lifeThere is an additional advantage called .

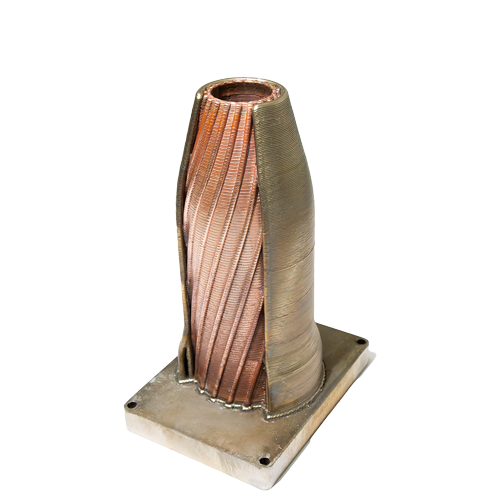

⑱ Dual Wire Capability and Multimaterial Printing

Meltio's printhead Two independent wire feedersIt has Using two different materials in one printYou can do it.

This makes it suitable for applications such as hard-facing and anti-corrosion coating.

Dual-material 3D printing can be performed quickly and easily, eliminating the risk of cross-contamination. We provide sustainable solutions.

Dual material Combustion Chamber: In625 + CuCrZr

4. Conclusion

In conclusion, PBF, powder DED, and Meltio each offer unique advantages tailored to different manufacturing requirements.

Powder Bed Fusion (PBF) is ideal for producing high-precision, detailed parts, making it suitable for industries such as aerospace and medical. However, its slow processing speed and high cost limit its use in producing large parts.

On the other hand, Powder Directed Energy Deposition (PED) offers faster printing speeds and wider material versatility, making it suitable for large part manufacturing and repair, but it offers lower resolution and surface quality compared to PBF.

Meltio technology offers great flexibility in hybrid manufacturing, with the ability to use multiple materials in a single print. Choosing the right technology based on your project's specific requirements, such as material requirements, part size, resolution, and cost, is crucial to achieving optimal results from additive manufacturing.