Hello, this is HDC, a consulting firm specializing in AM solutions.

Today, we'll delve deeper into the material known as titanium. We'll explore its outstanding mechanical properties, where it's used, and what industries are developing around this strong and versatile material.

Additive manufacturing (AM), commonly known as 3D printing, is a cutting-edge technology that is revolutionizing the manufacturing industry. Metal AM, in particular, is attracting significant attention in the aerospace industry due to its high material efficiency, short production cycles, and high degree of completion, requiring virtually no post-processing.

Representative materials used include titanium and its alloys, such as 316L stainless steel, AlSi10Mg, and Ti-6Al-4V, which are widely used to make high-density, high-performance parts.

index

- Titanium: The Metal of Strength, Flexibility, and Efficiency

- What is Ti-6Al-4V alloy?

- Limitations of traditional titanium processing methods

- Advantages of 3D Printing Titanium with Meltio Equipment

- Why is titanium processing difficult?

- Why Meltio's 3D Printing Technology is the Smart Choice

- Industrial fields where Ti64 material is mainly used

- Microstructure of Ti64 printed with Meltio system

- Mechanical properties of parts printed with Meltio

- Examples of real-world parts made of titanium

- In Closing – Titanium and the Future of 3D Printing

1. Titanium: Strength, Flexibility, and Efficiency

Over the past decade, additive manufacturing (AM) technology has moved beyond rapid prototyping and small-scale production.

It has now developed to a level where mass production is possible.

Currently, various metal alloys such as 316L stainless steel, AlSi10Mg, and Ti–6Al–4V are being utilized in actual industrial fields and are being successfully used to manufacture high-density, high-performance parts.

Among these, what is particularly noteworthy is that AM technology Capable of printing parts that are very close to the final shape

‘near-net-shape forming‘It has the capability to manufacture complex parts precisely without additional machining processes, which can greatly improve efficiency and productivity.

♦ W-LMD (Wire-Laser Metal Deposition) technologyIt can print parts with excellent microstructure,

That density is 99.998%This means that it can show performance that is superior to general casting and close to the level of forging.

▶ Complex parts in one go! – The true power of additive manufacturing

Additive manufacturing (AM) is a method of creating parts layer by layer based on a digital model.

This process allows complex shapes to be created in a single step, producing high-quality metal parts without the need for additional machining.

In particular, materials that are difficult to process and expensive, such as titanium alloys or super heat-resistant alloys, are difficult to handle using existing manufacturing methods.

In these cases, AM technology becomes a much more efficient solution.

▶ For titanium, which is expensive and difficult to process, AM may be the answer.

However, AM technology is attracting attention as an alternative that can drastically reduce titanium processing costs through design flexibility and process efficiency.

In the past, there were problems with impurities such as oxygen contamination, but with the development of technologies such as DED (Directed Energy Deposition),

Now, the level of impurity management has also improved significantly.

▶ Titanium parts made with AM also show better performance.

Titanium alloy parts printed using additive manufacturing are stronger than parts made using conventional rolling or casting methods. better mechanical propertiesIt is often seen.

The reason is that it is formed during the AM process. Unique microstructure This is because this structure improves the strength and durability of the part.

In this way, AM technology is bringing about a major change in the manufacturing method not only for titanium alloys but also for other metal materials that are difficult to process.

In short, it is positioned as a technology that will change the very method of metal manufacturing.

▶ Another characteristic of titanium – its properties change depending on heat.

Titanium changes its crystal structure at about 882°C. allotropic transformation It has a temper.

Simply put, it means that the desired properties can be controlled through heat treatment as the structure changes at high temperatures.

Additionally, titanium has the property of easily accepting other elements, making it a very advantageous metal for alloy design.

Another interesting property of this material is that its structural stability varies depending on the number of electrons in the added element.

▶ The biggest reason titanium is loved – its excellent corrosion resistance

One of the reasons titanium and its alloys are particularly noteworthy is their excellent corrosion resistance.

It reacts quickly with oxygen and forms on the surface. Thin and dense oxide filmThis oxide film forms and acts as a protective film that prevents external substances from penetrating.

Thanks to this protective layer, titanium Prevents oxidation and corrosion simultaneouslyIt is recognized as a metal that can maintain stable performance for a long time even in extreme environments.

2. Ti-6Al-4V alloy

Ti64 is a titanium alloy composed of 90% titanium, 6% aluminum, and 4% vanadium.

This alloy is Excellent mechanical properties, corrosion resistance, and high temperature resistanceIt has all of these features and is widely used in various industrial fields.

especially Ti-6Al-4V is the most widely used titanium alloy for industrial purposes.However, its use is so extensive that it accounts for about half of the world's titanium metal production.

The reason it is so widely used is simple.

This is because it has an excellent balance of various performances, including mechanical strength, corrosion resistance, and heat resistance.

It also has good processability, so it can be manufactured into various parts, and its performance can be adjusted through heat treatment. Flexible use in various industriesIt can be.

3. Limitations of traditional titanium processing methods

Machining titanium using traditional methods presents several challenges.

Representative examples include Constraints in terms of efficiency and cost-effectivenessThere is this.

For example, titanium is hard and has the property of easily wearing out tools. During processing, tools must be replaced frequently and maintenance costs are high.I will lose.

These characteristics make the processing process cumbersome and significantly increase operating costs.

In addition, titanium is expensive as a material, and methods that remove material (subtractive processes) such as cutting or drilling cause a lot of unnecessary material loss. The downside of increased wasteThere is this.

In addition to this Another problem is that welding is difficult.Yes.

Because titanium is very sensitive to oxidation, A properly protected atmosphere (oxygen-free environment) If you work without it, oxidation will occur easily.

This can make the welding process more complex and increase the overall production cost.

4. Advantages of Titanium 3D Printing Using Meltio

Meanwhile, the advent of 3D printing technologies based on systems like Meltio is offering several distinct advantages to titanium manufacturing.

One of the biggest advantages is that The fact that it can significantly reduce material wasteare you.

The existing subtractive manufacturing method involved a lot of waste because it involved cutting away raw materials to make parts.

3D printing to make parts Use only the exact amount of material neededdo.

Thanks to this, it is evaluated as a more sustainable and eco-friendly manufacturing method.

In addition, 3D printing Creating complex shapes that are impossible or very difficult using conventional methodsIt provides excellent design freedom.

This flexibility not only greatly expands design possibilities, Simplification of the manufacturing process that required multiple stepsThis can reduce overall costs.

Finally, Meltio's 3D printing technology is superior to conventional forging or cutting processes. Very energy efficientdo.

thus A more environmentally friendly and economical alternativeis attracting attention.

5. Difficulties with traditional titanium processing methods

Machining titanium using conventional methods presents several challenges.

These problems are Increased complexity and cost of manufacturing processesIt can lead to.

⚠️ Materials that are difficult to process

Titanium is so hard that tools wear out easily and work takes a long time.

However, using wire filler can be a more economical welding method, reducing material consumption and post-processing time.

⚠️ High production costs

Titanium is an expensive material in itself, and existing processes, such as cutting, cause a lot of unnecessary material loss.

On the other hand, additive manufacturing is a highly efficient process that uses only the amount needed, thus reducing material waste.

It is also advantageous in terms of energy efficiency as it allows for faster processing even with less laser power.

⚠️ The difficulties of welding

Titanium is a metal that oxidizes very quickly when exposed to air.

Therefore, welding requires a protective atmosphere that is free of oxygen, which makes the process more complex and expensive.

6. Why Meltio's 3D Printing is a Smart Choice

Meltio's 3D printing effectively solves many problems that arise from traditional methods. Modern alternativeare you.

Let's take a look at each of the specific advantages.

✅ Minimize material waste

Unlike traditional cutting processes, 3D printing creates objects by adding only as much material as needed.

By using only as much as needed, we reduce material waste and enable much more efficient production.

✅ More freedom in design

Even complex shapes and precise structures are easily manufactured with Meltio's printing technology.

This design flexibility is Enables more innovation, Even designs that were difficult to achieve using conventional methods can be realized.

✅ Reduce production costs

Because less material is used and the process is simplified The effect of lowering overall production costsThere is.

Reducing complex post-processing or multi-step processing also greatly contributes to cost savings.

✅ Excellent energy efficiency

Compared to forging or cutting, Meltio's 3D printing It requires much less energy.

Thanks to this A more environmentally friendly and sustainable manufacturing methodIt is evaluated as .

Thanks to these various advantages, Meltio's 3D printing A game-changing technology in titanium processingis emerging as a

It's a smart choice that satisfies all requirements: efficiency, cost-effectiveness, and environmental friendliness.

7. Major industries where Ti64 is used

Ti-6Al-4V, commonly referred to as Ti64, is a titanium alloy widely used in various industries.

It is highly versatile and provides performance that is well suited to the needs of specific industries.

■ Aerospace industry

Aerospace parts are Lightweight yet durable enough to withstand harsh environmentsThis is required.

Ti64 is Excellent strength-to-weight ratio, it is an ideal material for aircraft structural parts due to its excellent fatigue strength, fracture toughness, and corrosion resistance.

■ Automotive industry

Ti64 is **engine parts (valves, pistons)** and Suspension systemIt is mainly used in parts that require high performance.

It is preferred, especially in high-performance vehicles, because it can simultaneously satisfy both weight reduction and durability.

■ Energy industry

Wind power: Used in wind turbine components that require strength and corrosion resistance even in extreme environments.

power station: It can withstand high temperatures, so it is also used in generator parts and heat exchangers.

■ Marine industry

Corrosion is the biggest problem in environments that come into contact with seawater.

Ti64 is also suitable for marine structures, ship parts, and diving equipment due to its excellent corrosion resistance.

■ Defense industry

Ti64 is resistant to impact and high temperatures, and has excellent durability, so it is widely used in military equipment.

It is evaluated as a suitable material for parts where strength and reliability are important, such as armored vehicles and weapon systems.

8. Microstructure of Ti64 printed using Meltio system

The microstructure of Ti64 printed by additive manufacturing is greatly influenced by rapid solidification and grain growth direction.

Unlike forged Ti64, which generally has an equiaxial structure, columnar or acicular structures are often observed in the AM method.

This is due to the fast cooling rate, which is also evident in the Meltio system.

✅ Characteristic crystal structure of Meltio output

When looking at the microstructure of Ti64 printed with Meltio equipment, the grain boundaries are clearly distinguished.

This is a characteristic of a structure solidified in a molten state, and its characteristic is that it can be formed without heat treatment.

Additionally, as the heat supply during the output process is concentrated in a specific direction, the elongated crystals tend to grow in the direction of stacking layers.

⚠️ Bed-like structure and formation of α’ martensite

If we look inside the grain, You can see that an acicular structure has been formed.

This means that the martensitic α’ phase has been formed.

In LWDED (Low-Wire Directed Energy Deposition), rapid cooling Because of this, the α and β phases cannot be converted into a balanced distribution of tissues,

instead α’ phase with high mechanical strength but low ductility and fracture toughnessThis tends to form.

⚠️ Areas that can be improved through post-heat treatment

Additionally, No regions where the β phase is clearly formed between the grains are observed.

This is because post-processing heat treatment was not performed.

Heat treatment according to the Ti64 datasheet transforms the α and β phases into a more balanced structure.It can be.

in result, Ductility and fatigue strength of materialsThis creates the possibility to improve.

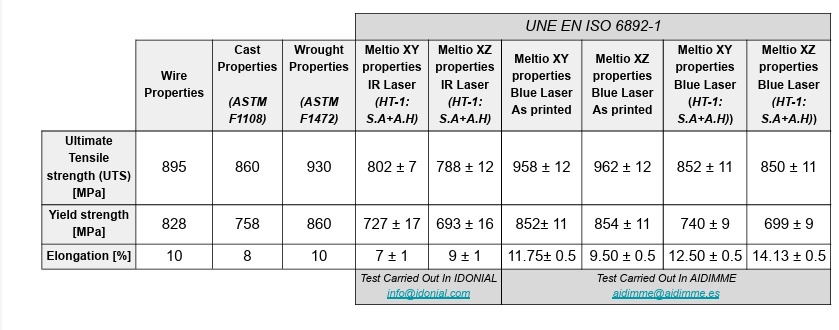

9. Mechanical properties of titanium printed with the Meltio system

As can be seen in the table below, the Meltio M600 system uses an inert chamber to suppress the presence of oxides within the microstructure.

Improves the properties of titanium.

These oxides reduce the ductility of the alloy and deteriorate its mechanical properties.

The table also Heat treatment can increase ductility and fatigue life by balancing the α and β phases.It also shows the point.

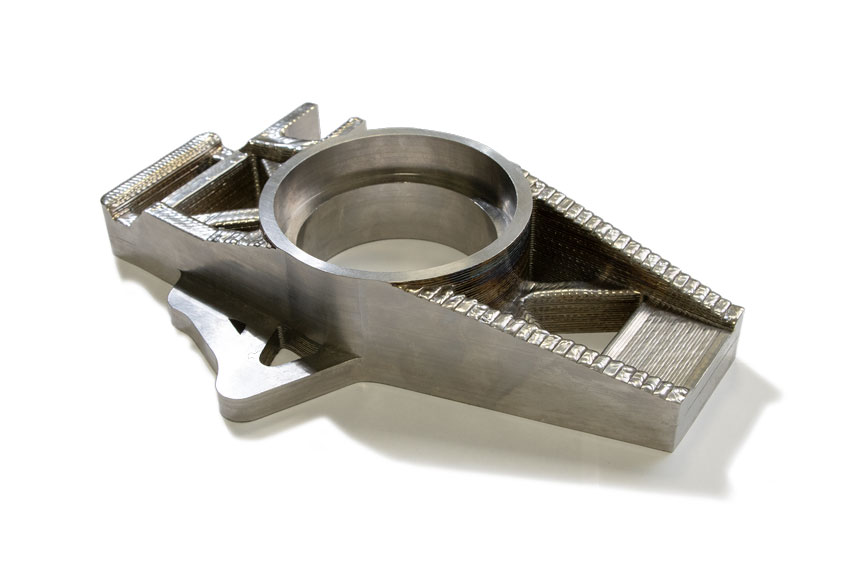

10. Parts made of titanium

Car Knuckle

Traditional manufacturing method

|

Manufacturing method |

explanation |

|

Forging |

Forming by heating and applying pressure to the metal. Suitable for simple shapes, but requires additional processing for precision. |

|

Casting |

Molten metal is poured into a mold to form it. It is suitable for creating complex shapes, but machining is still required to achieve the final specifications. |

|

CNC Machining |

Manufactured by cutting from a solid metal block. While highly precise, it is expensive and time-consuming for small-scale production. |

Meltio's Additive Manufacturing

|

characteristic |

explanation |

|

Design freedom (Design flexibility) |

It is possible to produce complex shapes and elaborate structures that are difficult to implement using traditional methods. |

|

lightweight (Weight reduction) |

Enables the production of lightweight components, reducing unsprung mass and improving handling and suspension responsiveness. |

|

A variety of material choices (Material options) |

Advanced materials such as titanium can be used for both strength and light weight. |

|

rapid production (Rapid production) |

Quick response to small-scale production and prototype production, no need for expensive molds or tooling |

|

Economical for small-scale production (Cost-effective for low volumes) |

No initial setup costs, making it ideal for custom designs or small orders. |

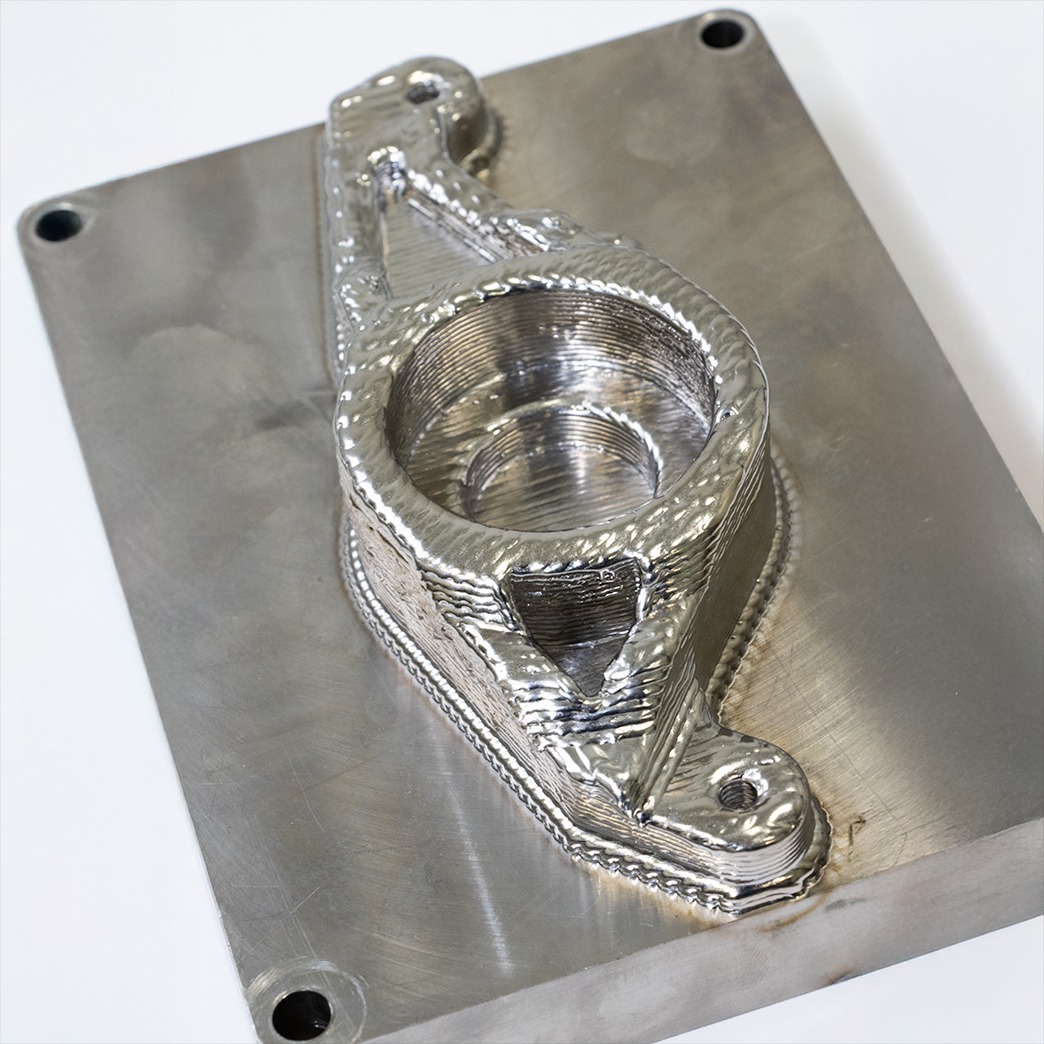

Titanium Aircraft Flap Actuator

Titanium is generally a very expensive material. Not just because of the raw material price,

This is because tool wear is severe during the cutting process, and the processing cost is also quite high.

So what if there was a way to reduce material waste and even shorten processing time?

Impac Systems Engineering found the answer in the Meltio M600 system.

In aerospace components, precision and repeatability are paramount.

The Meltio M600 meets industry standards by delivering near-net-shape parts with 99.8% density.

In comparison, when the same part is machined from a forged block,

It takes about 4 hours or more just for simple processing (excluding material waste).

On the other hand, the M600's hybrid approach

-

Material savings

-

Extended tool life

-

Reduce overall production time

-

It realizes three effects simultaneously:

-

The truth that “time = cost” is being proven again in the manufacturing field.

-

3D printing time: 4.5 hours

-

Processing time: 2.5 hours

-

Total time required: 7 hours

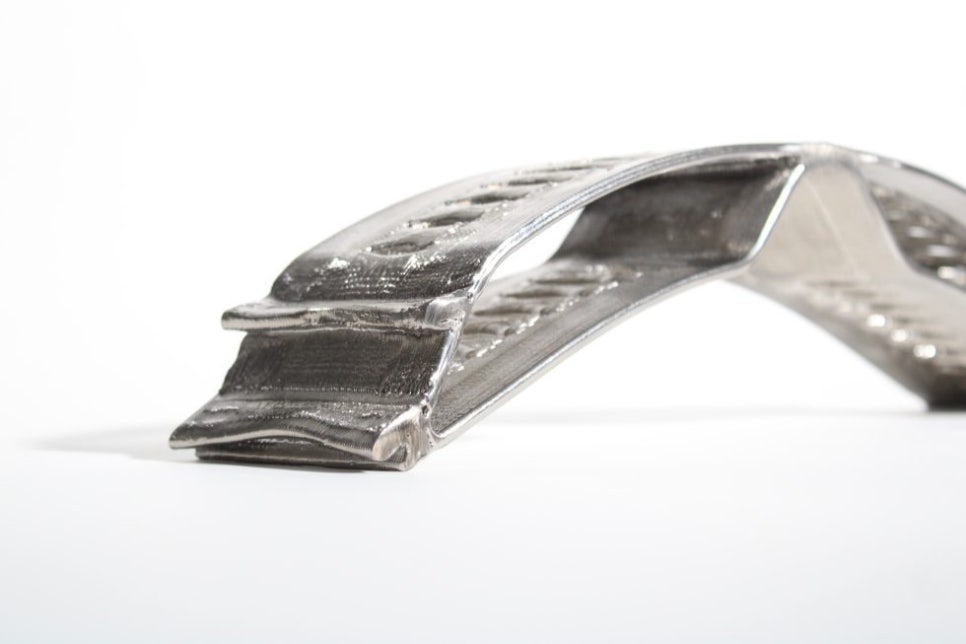

Compliant Mechanism

Architectural innovation is taking a leap forward with 3D-printed titanium!

Meltio's wire-to-laser metal additive manufacturing technology empowers designers and engineers to completely reimagine how structures are built.

One of the most interesting use cases is AA School of Architecture (AADRL) Affiliation Studio AngiusIt came from .

The project they carried out, ‘Alchemist’ Adaptive and mobile buildings, exploring

Topology-optimized titanium componentsWe aim to push the boundaries of design, efficiency and sustainability by applying it to structures.

-

Structural efficiency: Providing precision printed parts with minimal material waste

-

Material optimization: Achieving sustainable manufacturing through near-net-shape methods

-

Controlled flexibility: Flexible deformation up to ±12 degrees without structural damage

-

Seamless adaptation: Designed to react actively to changes in the external environment

-

Innovative motion implementation: A structure designed to move in response to a load of up to 227 N.

Conclusion

The development of new alloys specifically designed for additive manufacturing (AM) is becoming increasingly important.

Additionally, since AM is a near-net-shaping technology, it is also possible to produce innovative structures through this process.

Traditional manufacturing methods such as injection molding, casting, forging, and cutting are generally used. It causes significant waste of materials, It takes a long time to produce, High costs incurredThere is a tendency to do so.