Hello, this is HDC.

Today, we are leveraging Meltio's Metal Additive Manufacturing technology. For Inert Bubble

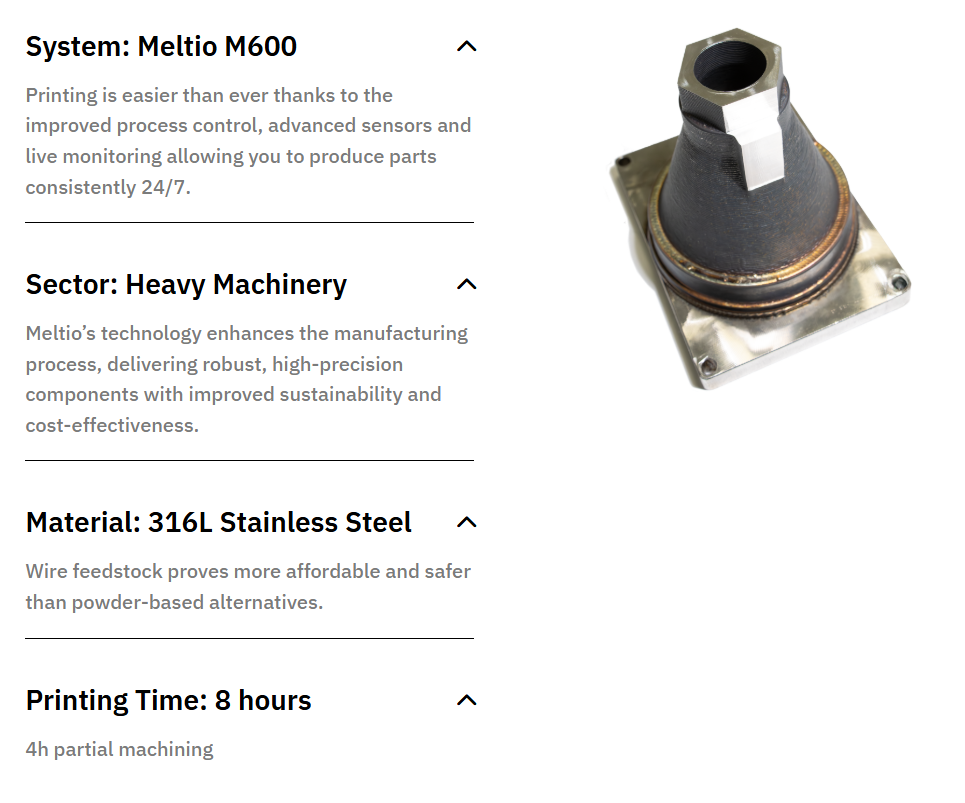

150mm diameter adapter plateWe introduce a case study of the production.

In the analysis phase of this case study, three approaches were compared:

- Using Meltio LMD and partial processing In-house production

- The existing method In-house pre-processing

- Outsourcing to external suppliers

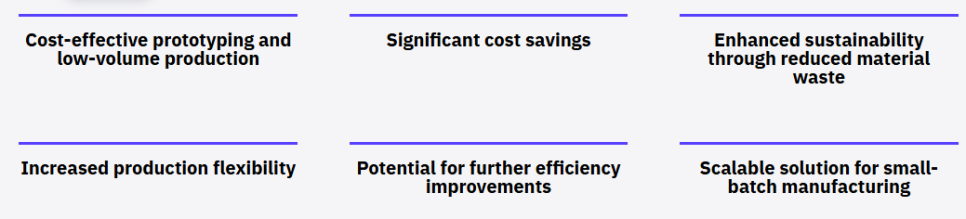

As a result, the manufacturing method utilizing Meltio is Cost savings, material efficiency, and production flexibility It provided a significant advantage in terms of

It has been evaluated as the best option for small-scale production or prototyping.

▶ What were the limitations of the existing manufacturing method?

Traditional manufacturing methods have many inefficiencies.

Especially when machining solid bar (stock) materials, The buy-to-fly ratio is extremely low.

For every single part produced, more than 40 kg of material was wasted.

Additionally, the machining process itself was inefficient. Using non-optimized CNC equipment,

Processing times were bound to be longer and productivity lowered.

These limitations are This was even more evident in small-scale production.

This is because the production cost is high and profitability is bound to be low due to the inefficient use of materials and long processing times.

If you use outsourcing processing here, Problems arose where lead times became longer and production response speeds slowed.

To summarize, the main challenges faced by existing manufacturing methods were as follows:

- High material waste (low buy-to-fly ratio) resulting from traditional cutting processes

- Increased overall manufacturing costs due to increased costs of raw materials and consumables

- Long processing times due to inefficient CNC equipment

- Increased lead times and reduced production flexibility due to increased reliance on outsourcing

- Low profitability, especially in small-scale production

▶ Approaching manufacturing innovation with the Meltio method

To overcome the limitations of conventional manufacturing methods, we introduced Meltio's additive manufacturing process.

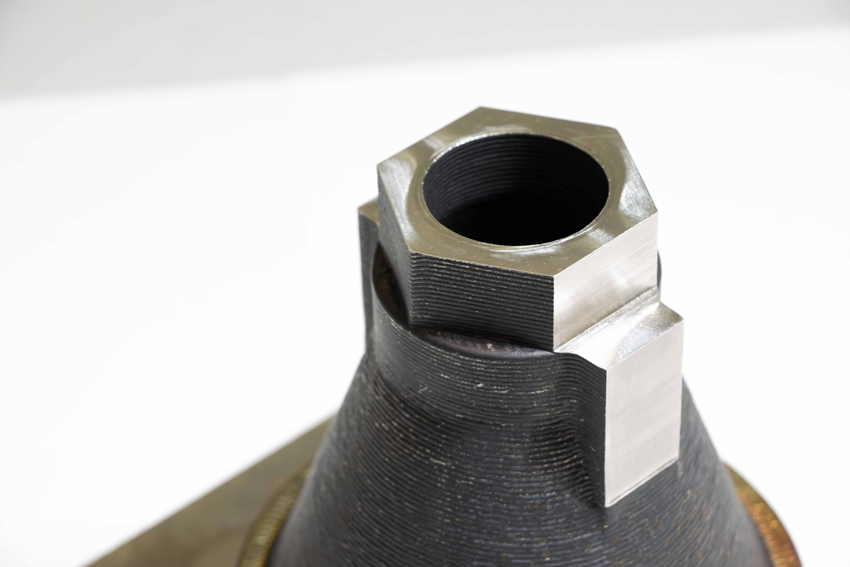

The core strategy is Utilizing Meltio's LMD (Wire-Laser Metal Deposition) technology,

The method was to print the adapter plate in a shape close to the final part (Near-Net Shape) and then selectively process only the main functional surfaces.

This approach Significantly reduce the amount of material that needs to be removed during the finishing stage, which has the effect of reducing unnecessary waste and processing time at the same time.

By integrating additive and subtractive processes into one process,

We were able to optimize material utilization while still maintaining the required precision in key areas of the component.

Key Points of Meltio LMD Method

- Wire-LMD manufacturing: Output the approximate shape of the adapter plate with Meltio LMD and selectively cut only the functional surface.

- Minimize processing: Most of the part surface remains in its original state.

- Buy-to-Fly Ratio Optimization: Achieving significantly improved material efficiency compared to traditional processing

The results were clear.

Meltio's method allowed the total production cost to be reduced to just 264.54 euros.

This was a breakthrough compared to existing methods.

▶ Innovatively improved buy-to-fly ratio to 1.11

One of the greatest achievements of the Meltio method is The fact that the buy-to-fly ratio was raised to 1.11no see.

This is practically a level of material waste that is almost non-existent compared to conventional methods. It showed overwhelming material utilization efficiency.

Also, this approach Minimizing waste and improving the sustainability of the production process.I ordered it,

A flexible solution that can easily be scaled for small-volume production or custom parts manufacturing.It has competitiveness in this respect.

As CNC machining setups are further optimized in the future, the savings in machining time and cost are expected to be even greater.

Above all else Because we can integrate metal 3D printing and post-processing in-house, Rapid prototyping and design verification are now possible without relying on external partners.

This is a powerful advantage that can dramatically accelerate a company's product development speed.

▶ Meltio Hybrid Manufacturing vs. Traditional Manufacturing: A Clear Difference Confirmed in Numbers

Meltio LMD + selective machining method is compared to conventional cutting machining or outsourcing manufacturing method.

Excellent results in all aspects including cost, material efficiency, and lead time.showed.

| Manufacturing method | Total cost (€) | Buy-to-Fly ratio |

| Meltio LMD + CNC (optional machining) | 264.54 € | 1.11 |

| Traditional cutting processing | 524.79 € | 19.74 |

| Outsourced production | 700.00 € | – |

▶ A Strategic Approach to Better Manufacturing

Meltio's manufacturing approach has proven to be the optimal solution for producing parts like adapter plates more efficiently and competitively, especially in low-volume production environments.

By combining the advantages of additive manufacturing and subtractive manufacturing,

We have implemented a balanced manufacturing method that not only improves production efficiency and reduces costs, but also reduces environmental burden.

This accelerates the transformation of production processes to become smarter, more sustainable, and more responsive to market changes.