Hello, this is HDC.

Today, we'd like to introduce Meltio's global case, which has enabled complex metal parts in the energy industry to be produced with a single output.

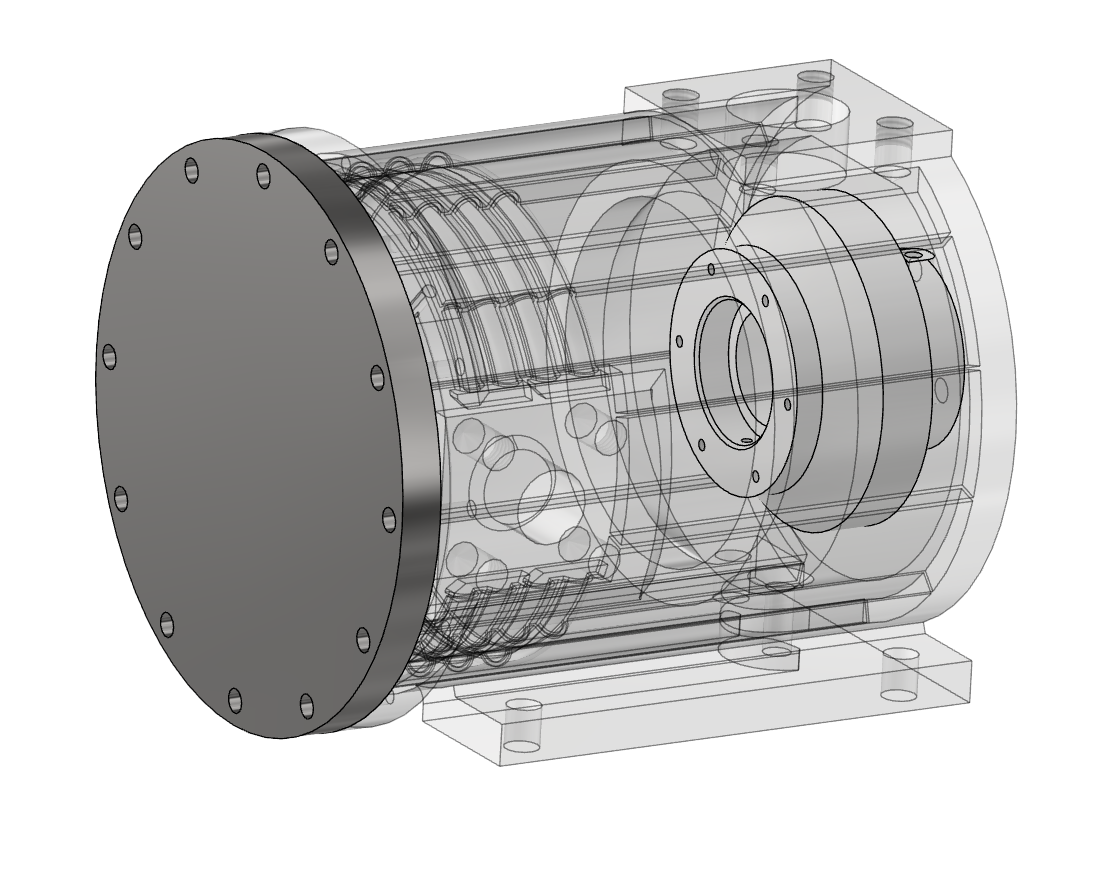

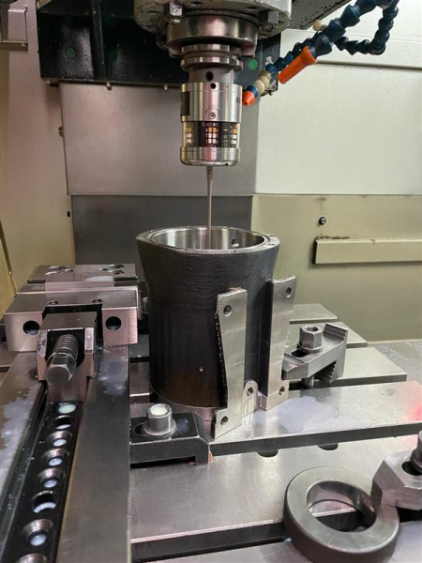

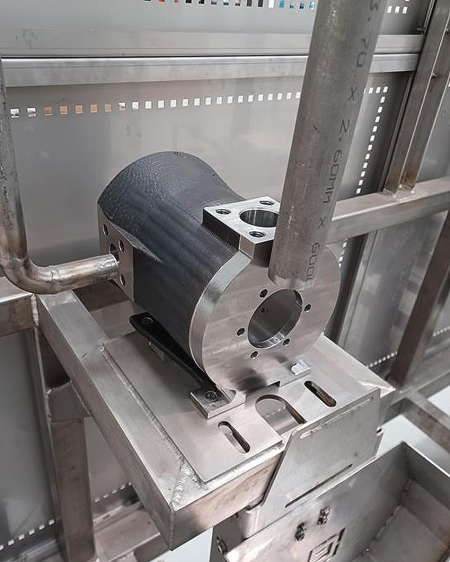

ROEZ, a Czech R&D specialist, has secured both productivity and design freedom by producing a turbine case with an internal flow structure in a single output using the Meltio M450.

This case is a meaningful one that can be applied not only to energy, but also to defense, shipbuilding, and aerospace.

▶ The Potential of Metal Additive Manufacturing: A Case Study of Roez

How can we efficiently manufacture the complex components required in the energy industry?

Czech R&D specialist company ROEZ R@DTo satisfy the design flexibility, manufacturing speed and sustainability of key components.

We have introduced Meltio's metal 3D printing solution.

▶ Technological limitations in manufacturing high-efficiency energy components

The turbine case, a key component of a heat recovery system utilizing low temperature differences, requires extremely complex internal flow paths and precision.

The manufacturing process is complex and there are significant cost and material constraints with conventional CNC machining or powder-based 3D printing methods. ROEZ R@DA new solution was needed that could produce complex shapes, including internal structures, in a single build without separate post-processing.

✅ Rapid prototyping and iterative improvement of complex parts without relying on external suppliers

✅ Effectively reduces lead time and costs compared to traditional manufacturing or outsourced 3D printing.

✅ Advanced materials that were previously difficult to apply can now be used in actual processes.

✅ Scalable additive manufacturing solutions can be integrated into your production line with minimal disruption.

▶ Technical strengths provided by Meltio M450

✅ Plug and Play: Ready to use without welding or separate equipment

✅ Multi-material compatibility: A single machine can output various alloys such as S316L, ER70, Ti, and Ni.

✅ Operational Automation: Intuitive interface + remote monitoring with minimal staffing

✅ Cost competitiveness: High performance achieved using only wire materials without electrode customization

✅ Implementing complex shapes: Implementing a turbine case with an internal Euro as a single output

|

|

[Actual Output Example]

- Equipment used: Meltio M450

- Industry: Energy

- Material: 316L stainless steel

- Output time: 85 hours

In this way, Meltio's solutions address complex geometries, material flexibility, and manufacturing speed in the production of high-value-added energy components, offering a rapidly applicable alternative in real-world industrial environments.

If you're looking for sustainable manufacturing innovation, Meltio's additive manufacturing technology could be the answer.