Hello, this is HDC.

Tool steel plays a very important role in manufacturing today.

Designed to withstand extreme stress, high temperatures, and wear, they deliver reliable performance in demanding industrial environments, from die casting to injection molding.

Meltio is expanding the possibilities of metal additive manufacturing.

Meltio continues to expand the range of tool steels it can reliably print using wire-laser-based metal deposition (LMD) technology.

Today Meltio tested H11, H12, H13, P20, M7 Focusing on tool steels such as

Each material Mechanical properties, printability, application examples, and recommended heat treatment conditions Introducing the back.

Through this, we hope to provide practical assistance in selecting the right material for your industrial site.

| Tool Steel Overview (Material Overview)

Tool steel is broadly classified into carbon steel, alloy steel, and high-speed steel.

It is hardenable and heat treatable, so it is used to shape or cut other materials such as molds, dies, and cutting tools.

The martensite content of tool steel is a key factor in determining its mechanical properties.no see.

Martensite is formed when austenite is rapidly cooled (quenched).

It plays an important role in increasing hardness, wear resistance, and impact resistance.

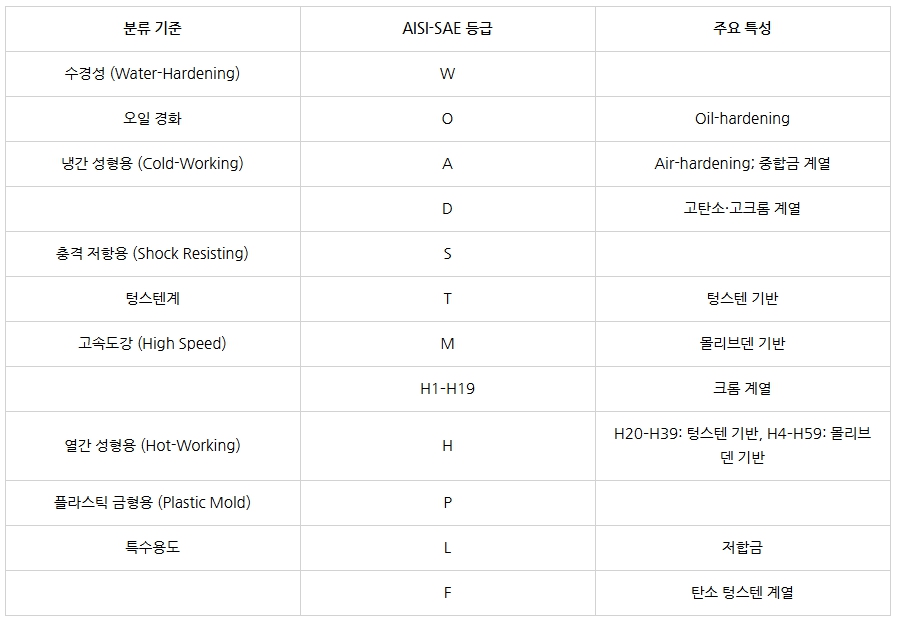

Typical tool steel classifications are as follows:

Currently, the most frequently used and frequently printed tool steel in Meltio is H11no see.

This material is classified as an official layerable material by Meltio.

Detailed material properties can be found in the datasheet on our website.

In addition, Meltio H12, H13, H17, P20, M7 We have completed lamination tests on tool steels such as:

| H11 tool steel

H11 is one of the most widely used tool steels.

It is mainly used in processes that require resistance to repeated impact and wear at high temperatures, such as forging, die casting, extrusion, and plastic molding.

This material is highly resistant to wear, deformation, and high temperatures.

It is also suitable for cases where high performance is required only in certain areas rather than the entire component.

H11 has excellent weldability and bonding strength.

It is also effective in forming a uniform and solid coating layer on these areas.

[Characteristics and heat treatment process during additive manufacturing]

H11 is laminated in a hardened state during 3D printing.

In this case, processing is difficult and ductility is low. A condition prone to crackingIt becomes.

So, generally, except for cladding (surface addition) or simple functional addition,

A proper heat treatment process is absolutely necessary.

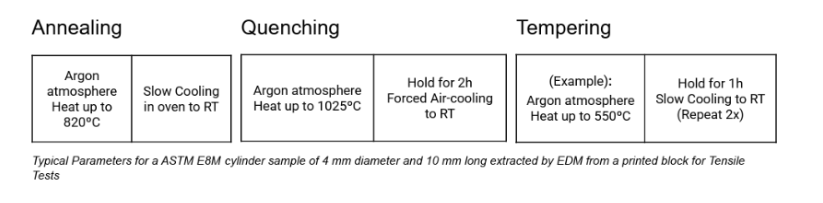

Ideal heat treatment sequenceis as follows:

-

-

Annealing

-

– Apply immediately after printing, before removing from the build plate, to reduce internal stress and make processing easier.

Example: Heating to 820℃ in an argon atmosphere, then slowly cooling in an oven.

-

-

Quenching

-

– Heat to 1025℃ and maintain for 2 hours → Cool using air cooling method

-

-

Tempering

-

– Heat to 550℃ → Maintain for 1 hour, then cool slowly (recommended to repeat 2 times)

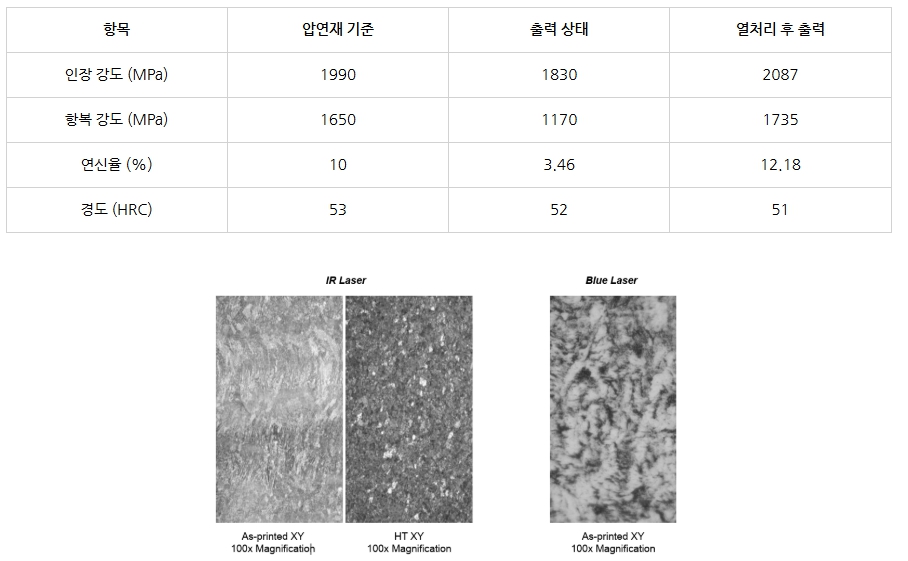

[Output speed and mechanical characteristics]

H11 is not the fastest printing material, but

(150g/h for blue laser, 141g/h for infrared laser)

A material with very high demand and user satisfaction in industrial settings.no see.

-

An external testing agency analyzed 10×10×60 mm samples according to ASTM E3-11:2017, and found that both immediately after printing and after heat treatment It was confirmed to have a uniform microstructure.It's done.

-

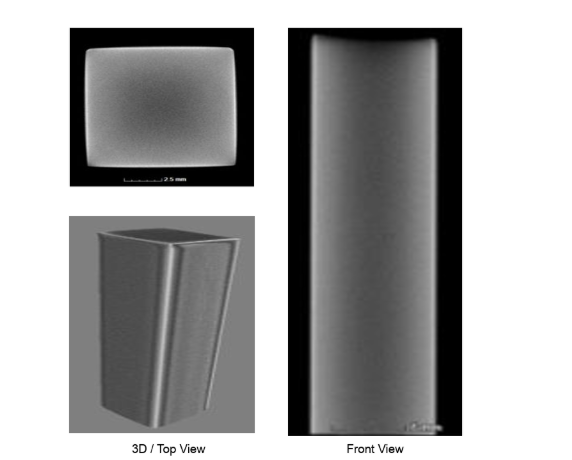

Also through CT scan Internal quality without any voids or defects, and the resolution is very precise at 24μm/pixel.

[Dual-material lamination and application possibilities of H11 and 316L stainless steel]

H11 tool steel is Materials for dual material printing or reinforcementIt is also a material in high demand.

In particular, it is important to understand the behavior when laminating H11 on 316L stainless steel.

It is very important in terms of cladding or composite applications.

Meltio is designed to analyze the interactions between these materials.

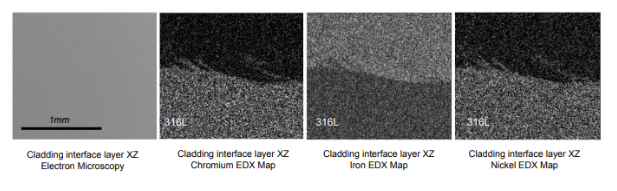

EDX (Energy Dispersive X-ray Analysis) MapWe used this to precisely visualize the dilution area.

Below is a map showing the distribution of each element (chromium, iron, nickel) along with electron microscope images.

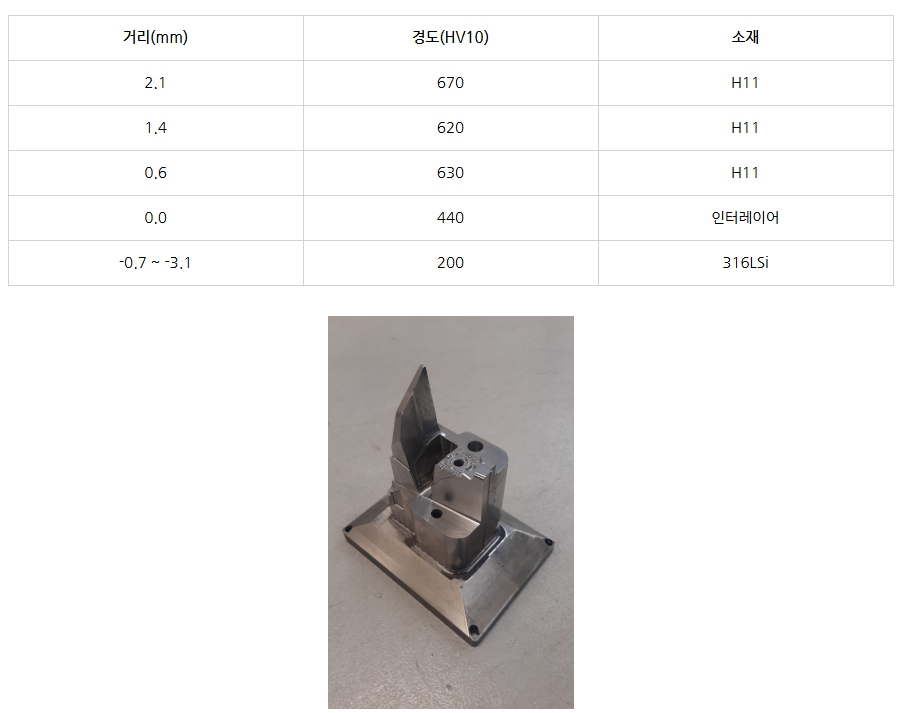

As a result of measuring the hardness change in the transition region between H11 and 316L,

Even with a single cladding layer Sufficiently stable and uniform mechanical propertiesIt has been confirmed that it is possible to secure .

The test was conducted by cutting a block of size 30×60×20 mm using EDM method.

Verified Density Parametrization MethodIt was carried out as follows,

Analyzed by an external expert testing laboratory according to UNE-EN ISO 6507-1 standard.

One of the representative application cases utilizing Meltio technology is H11 tool steel is laminated into a single wire

How to make injection mold insertsno see.

In the conventional method, inserts are made by machining solid blocks, so there is a lot of material waste.

The more complex the shape, the longer the processing time.

but Meltio's LMD lamination methodSilver insert It can be directly output close to the final shape.

It can drastically reduce material usage and processing time.

This method is especially effective in cases where:

-

-

Custom insert manufacturing

-

small-scale production

-

also, A much more flexible production strategy while maintaining mechanical performance.can be established

It is both more economical and more productive than conventional methods.

The photo below shows the actual mold insert result after machining on the build plate.

As the mold industry's interest in Meltio technology has recently increased,

A heterogeneous material output process combining H11 and CuCrZr is also under development.is in.

For example, in H11 material Built-in cooling channelsAnd, by applying a shape design that combines CuCrZr inserts

Attempts are being made to simultaneously improve mold performance and durability.

Such composite material output is Implementing complex shapes, improving cooling efficiency, and manufacturing high-value-added insertsIt is very advantageous.

| H12 tool steel

H12 has better wear resistance than H11 and provides more stable performance even when used for long periods in high-temperature environments.

However, some toughness is sacrificed.

It has a slightly higher carbon content and a lower chromium content, but the addition of tungsten improves hardness and thermal stability.

Therefore, rather than impact strength or ductility, Materials suitable for environments where heat resistance and wear resistance at high temperatures are importantno see.

H12 is for processing high-strength steel. Hot forming tools, for molding glass or high-temperature plastics mold,

Used in sintering and powder metallurgy processes die It is often used on the back,

It is useful in all situations where maintaining shape and hardness at high temperatures is important.

Also, H12 One of the most popular materials for mold operations involving abrasive wear in high-temperature environments.no see.

For example, it is frequently used in the production of extrusion inserts for difficult-to-machine alloys requiring heat resistance, or mold parts used in high-temperature stamping.

| H13 tool steel

H13 is a representative hot-worked mold steel with a good balance of heat resistance, thermal fatigue resistance, hardness, and toughness.

It is one of the most widely used tool steels worldwide.

Compared to H11 and H12, H13 has higher vanadium and molybdenum content. Excellent resistance to thermal shock and wear resistance even during repeated heating and cooling cyclesIt shows.

These properties make H13 highly resistant to rapid temperature changes and mechanical stresses in tools, without sacrificing dimensional stability or service life.

also, A representative material widely used in parts that undergo repetitive thermal cycles, such as core pins or inserts.This is also true.

It is highly reliable and resistant to cracks and thermal cracks, and exhibits stable performance even in various thermal and mechanical environments.

The most widely chosen and best-selling material for global hot molds.You can say that.

| P20 tool steel

P20 is pre-hardened tool steelIt is widely used in plastic injection molds and die-casting molds for low-melting-point alloys.

Since it is already heat treated (typically 30-36 HRC) upon shipment, there is no need for a separate heat treatment process after processing.

It can be used directly for mold making.

The advantage of making the manufacturing process quick and easyThere is this.

P20 has moderate hardness, excellent processability, and good toughness.

Highly suitable for manufacturing medium to large mold bases or general mold parts, not in high temperature or high wear environments.do.

Typically used for cavities of plastic injection molds, core inserts, die-casting molds for aluminum and zinc,

It is also used in mold frames, where dimensional accuracy and ease of processing are important.

Of course, it is not suitable for high temperatures or extreme wear conditions,

A reliable and practical choice for general purpose mold making.It becomes.

It provides a balanced combination of properties between cost, processability, and mechanical performance.

| M7 tool steel

M7 is a material of the molybdenum-based high-speed tool steel (HSS) series.

It has higher carbon and vanadium content than the more commonly used M2, resulting in higher hardness and edge retention at high temperatures.

Thanks to you High-performance cutting tools that require both high temperature resistance and wear resistanceIt is a material particularly suitable for .

M7 can maintain its hardness even at red-hot temperatures (high enough to cause the tool to glow red during operation).

Even during high-speed machining, tool wear can be reduced and a long life can be expected.

Generally, it requires more performance than the M2, but like the M42, Steel grades with high cobalt content are preferred when price or brittleness is a concern.

The M7 is a good alternative.

Typical uses include twist drills, end mills, broaches, reamers, and punches.

especially High compressive strength and durabilityIt is widely used in tools for cold working applications.

Like other HSS series, M7 also Balanced characteristics between hardness and toughnessI have

It withstands shock and pressure generated during cutting and provides stable processing performance.

|Why Meltio's tool steel?

Building on these advantages, Meltio's additive manufacturing is revolutionizing the way tool steel is made.

Efficient and cost-effective manufacturing solutionsIf you are looking for , Meltio may be the answer.

|Main application areas of tool lectures

▶ Mold and Tooling Industry

Meltio's technology enables rapid production of near-form parts, making it ideal for on-demand manufacturing and repair, as well as hybrid material applications.

▶ automotive industry

It is used in tool manufacturing for rapid, repeatable production in molding processes. Its exceptional thermal fatigue resistance makes it particularly effective in cost-saving short-run production and prototyping.

▶ aerospace industry

We manufacture high-hardness tools (such as M7) with excellent wear resistance, making them ideal for precision, high-performance, low-volume production tooling. We also offer solutions that facilitate lightweighting and the integration of complex shapes.

▶ heavy industry sector

Partial reinforcement or repairs can be performed to extend tool life, reducing replacement cycles and the cost of large tools. This is effective in producing high-temperature tool steel that can withstand extreme environments.

*W-LMD technology can produce parts with excellent microstructure and density up to 99.998%, providing quality that surpasses the characteristics of cast products and rivals the level of forging.

Advanced additive manufacturing technology utilizing tool steel

The ability to print high-performance tool steels with precision and consistency means that

Shortened delivery times, reduced raw materials, and greater design freedomopens up new possibilities for manufacturers who want to

Whether you're reinforcing parts with H11, building high-temperature molds with H12, or optimizing mold inserts with P20,

Meltio's technology helps you maximize the potential of these tool steels.

Meltio continues to test and verify various materials,

Through this, the entire industry Real performance improvements and cost savingsWe are expanding our range of additive manufacturing solutions.

This is the way to maximize manufacturing efficiency without sacrificing strength, durability, or flexibility.