Hello, this is HDC.

Extending the life and reducing costs of aerospace components; And is there a technology that can satisfy all of these requirements simultaneously, including the ability to withstand extreme environments?

Meltio's unique DED technology transforms robotic arms into powerful 3D printing systems. Together with CATEC, we are completely revolutionizing the R&D and production processes in the aerospace industry.

Let's take a look at the collaboration between CATEC and Meltio.

Today's aerospace industry is unparalleled

Quality, extreme environmental performance, and absolute reliabilityRequires.

All core components must be designed for maximum safety and efficiency;

To address these challenges, Spain's Advanced Center for Aerospace Technologies (CATEC)

It has firmly established itself as a leading applied research and technology development institution in Europe.

The technology that CATEC has chosen as the answer to future aerospace manufacturing is MeltioThe unique

Wire-laser Directed Energy Deposition (DED) It's technology.

This strategic partnership covers the entire production and repair process of metal components.

It opens up innovative possibilities and is crucial for related companies. Competitive advantageprovides.

Meltio's DED Technology: Changing the Paradigm of Aerospace Manufacturing

Meltio's DED solution is not simply a standalone 3D printer.

existing CNC (computer numerical control) machines, multi-axis robotic arms, and standalone systemsto Fully integratedDesigned to be It is a flexible and scalable platform.

This compact and adaptable approach We provide optimized solutions for the constantly changing aerospace R&D and manufacturing environment.

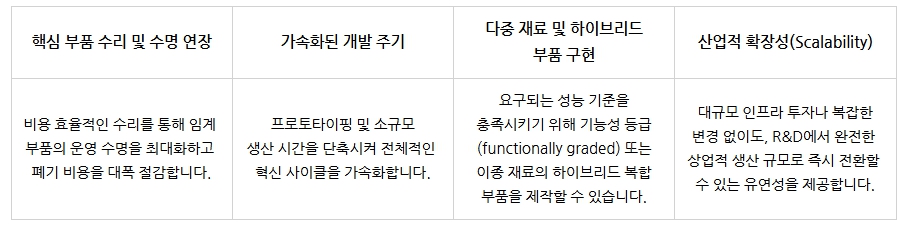

|The Strategic Advantages of Meltio Technology (Aerospace Industry Focus)

Unlike other additive manufacturing technologies, Meltio's solution CNC machine, robotic arm, and standalone 3D printerto Seamless integrationIt is designed to be so.

This compact and flexible approach provides an ideal solution for aerospace R&D environments where scalability and adaptability are key.

The most crucial benefits that Meltio technology offers in aerospace include:

Meltio Engine: A Metal AM Solution Without Size Constraints

Meltio's Engine Integration kit is a complete solution for industrial robot arms. Transform your machine into a powerful metal 3D printing system with no inherent size constraints.

This platform is Fabrication, repair, cladding, and feature addition of large and complex partssuch It perfectly copes with difficult tasks.

Meltio Engine is manufactured by ABB, Kuka, Fanuc, Yaskawa, Siemens, etc. Almost all major robotic arm manufacturers in the marketof Easy to integrate and compatible with systems.

Proven Technology: Beyond Aerospace to Across Industries

The partnership with CATEC solidifies Meltio's already impressive list of successes in high-performance industries.

-

-

Automotive: Companies such as DMZ and ERM are using Meltio technology to produce exhaust manifolds and turbo parts, reducing manufacturing time. Up to 70% It has been shortened and has demonstrated excellent performance under extreme environmental conditions.

-

Defense: The US Navy used Meltio to destroy the USS Arleigh Burke. naval eductor Discontinued spare parts, etc. within 58 hoursWe have successfully replicated this rapidly, which is a critical application for impellers and mission-critical components where downtime is absolutely unacceptable.

-

Energy: Roes s.r.o. manufactures complex turbine housings. single componentWe achieved an engineering breakthrough that completely eliminated the assembly process and dramatically reduced overall lead time by manufacturing with .

-

🎯 CATEC Collaboration Case Study

-

Industry Sector: Aerospace

-

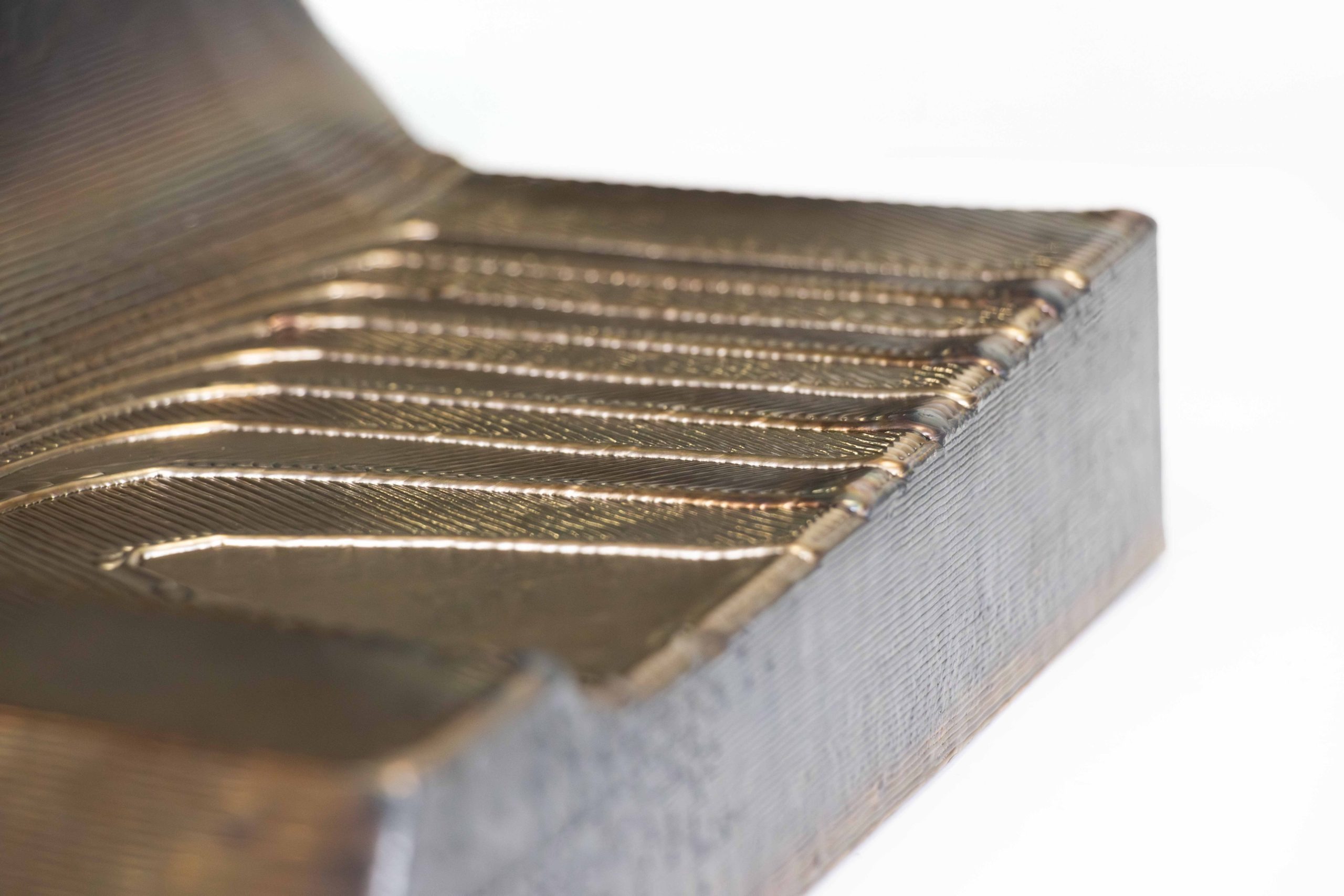

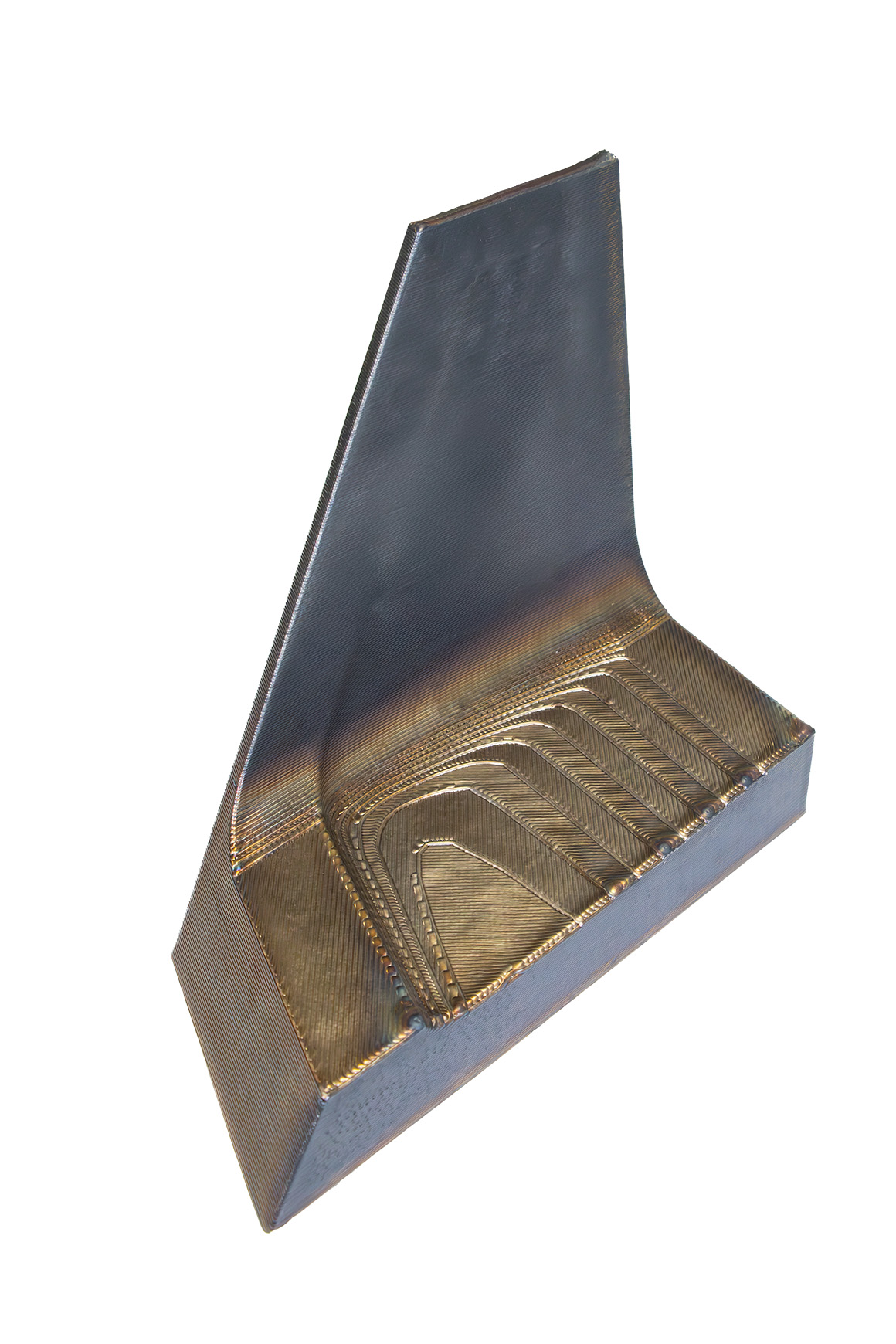

Main materials: Invar

-

Material properties: Wire-based feedstock is more cost-effective than powder-based alternatives. Economic efficiency and handling safetyThis is far superior

-

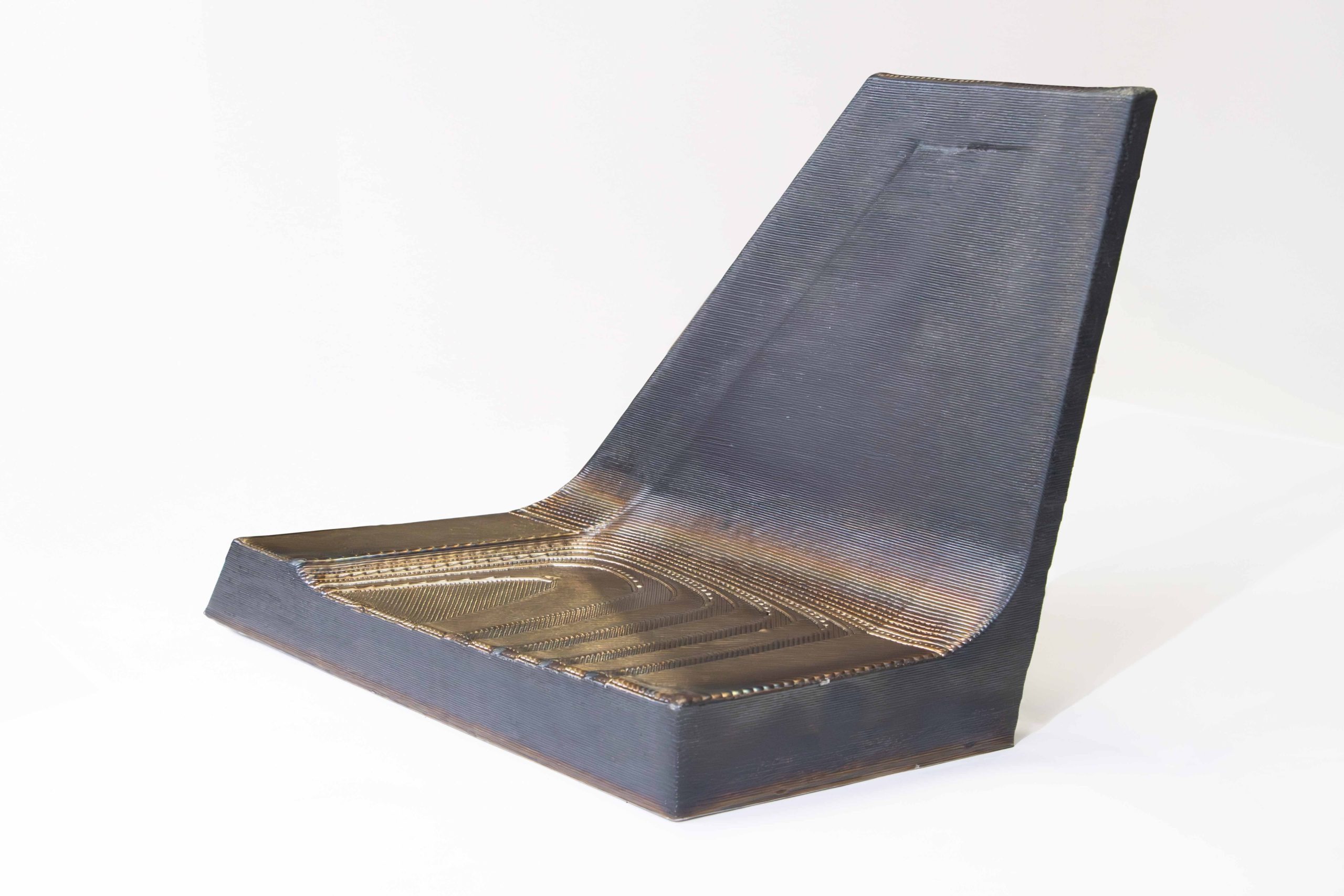

Process time: 71 hours 34 minutes Successfully additively manufactured high-reliability aerospace metal parts (parts in the image) for the first time in a long time.

|Conclusion: A Sustainable Future Driven by Technological Alliances

The collaboration between Meltio and CATEC is a partnership between industry and research centers that drives technological advancements.

It will be recorded as the clearest best practice.

Meltio's wire-laser DED expertise combined with CATEC's aerospace R&D leadership

This alliance is the future Innovation, Sustainability, and Global CompetitivenessIt clearly presents a new path for .